Many engineers and technicians in the motor control industry consider a programmable logic controller (PLC) a necessary component for variable frequency drive (VFD) control. This may have been true years ago, but VFD technology has improved and made technological advances in recent years. VFDs have developed so that the need to install and program a PLC, which was previously required for many applications, has been eliminated. This advancement results in overall cost and space savings. Additionally, the wiring and programming complexity is reduced significantly.

A VFD As a PID Controller

A common example in which a VFD provides the functionality of a PLC is a pumping application. Many pumping applications use a proportional-integral-derivative (PID) loop to determine the required motor speed. A PID loop will consist of a set point, feedback and tuning for the PID loop. Frequently, a PLC is used to process the entire PID loop and output an analog speed reference to the VFD.

In this case, the VFD is being underestimated since most entry-level VFDs have their own PID loop, which can be enabled and set up with only a small number of parameters. The set point is entered directly into the VFD’s programming. This eliminates the need to switch between the VFD’s keypad and a PLC’s computer software. Feedback from a transducer is sent directly to the VFD’s analog input.

With these two commanding values, the drive can determine if the motor should speed up or slow down to meet the set point. This maximizes energy efficiency because the motor only runs fast enough to meet the demand of current the set point value. Cost is reduced because a PLC does not need to be purchased or programmed. Also, space is dramatically reduced because the entire process operates using only the VFD.

Pump & Motor Protection

A PID process loop is a relatively simple example that only scrapes the surface of the potential processing power of a VFD. VFDs can protect the pump motor and the application with minimal programming. On a specialty pump VFD, protection can be set up in three basic steps: level, delay and action.

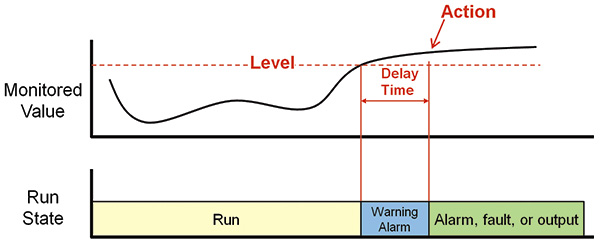

The level is a value at which point a protective feature is triggered. This level can be based on values such as current, frequency, voltage or feedback.

The delay will determine the amount of time the monitored value can remain above or below that level before action is taken. After the delay time expires, an action is taken, which can include faulting out the VFD, alarming or closing a digital output contact on the drive (see Figure 1).

Figure 1. Most VFD protective and application-specific programming can be broken into three parts: a level, a delay and an action.

Figure 1. Most VFD protective and application-specific programming can be broken into three parts: a level, a delay and an action.The VFD has the ability to monitor current, frequency, feedback, voltage and many other critical values. The ability to monitor these values also gives the VFD the ability to protect countless VFD and pump-related components, which can avoid potentially hazardous running conditions.

Loss of Prime

Consider a condition in which prime is lost on a pump’s suction side. The most simple and effective way to determine that prime has been lost is to monitor the current drawn by the pump motor. To protect the pump from a loss of prime, a motor current detection level in the VFD must be set just above the motor’s no-load current. If prime is lost, the current drawn by the motor will be reduced. If the output current drops to the no-load current, which is right below the set detection value, the VFD will perform the desired action after the programmed delay time. This protects the pump from overheating because of dry-run conditions without the need for additional components. Those three basic programming steps (level, delay and action) for loss of prime are copied and pasted throughout the majority of a VFD’s programming.

High Pressure

Another example is high-pressure relief or detection, which is required on any pump application. With a VFD that controls a pump, a high feedback level can be programmed into the VFD. Following suit, a delay time and an action for this new condition must be set. Once properly set up, if the system’s pressure reaches the high feedback level, the VFD can halt pump operation before damage occurs. The VFD can also be programmed for a low feedback detection situation that functions in the same way.

Other Benefits

In addition to providing protective features, VFDs offer many programmable functions that provide benefits for different applications. Irrigation systems commonly consist of long and intricate plumbing lines. When an irrigation system operates, it must first pre-charge the system. Pre-charging simply means running the VFD at a relatively low fixed speed to slowly fill or pressurize the system. Pre-charging is beneficial because it eliminates any hammering of valves that may occur with an otherwise fast pump speed.

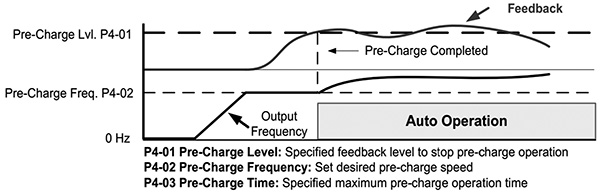

Setting up the pre-charge function only requires three parameters as in the previously mentioned examples. For pre-charge, a fixed frequency must be determined. This frequency is called the pre-charge frequency and is the rate at which the VFD will run while in pre-charge mode. Pre-charge mode will activate when a VFD receives a run command, and it will continue to operate at the programmed, pre-charge frequency until one of two criteria is met (see Figure 2).

Figure 2. The VFD ends the pre-charge operations once the maximum pre-charge time expires or the pre-charge level is met.

Figure 2. The VFD ends the pre-charge operations once the maximum pre-charge time expires or the pre-charge level is met.This requires two additional parameters—the pre-charge level and pre-charge time. The sole function of these parameters is to end the pre-charge operation. The pre-charge level uses the transducer’s feedback to determine at which level to end the pre-charge process. This is usually in pounds per square inch (psi). Alternatively, the pre-charge time is the maximum time the VFD should run in pre-charge mode, regardless of whether the feedback level is reached.