Last of Two Parts

Motors represent a significant energy expense for any industrial plant. To minimize cost, users can ensure their motors run as efficiently and reliably as possible. Operators should focus on caring for bearings and windings, the two components that most commonly lead to motor failure.

Last month's Motors & Drives column (Pumps & Systems, May 2015) detailed some common causes of premature bearing failure, such as lubrication and vibration, and steps that motor users and manufacturers can take to prevent these problems. Part 2 of this series will focus on winding failures.

Winding Failures

After bearing failures, winding failures are the next highest failure mode in motors. Windings fail because of temperature, coating or caking on the frame, overloading, and other problems.

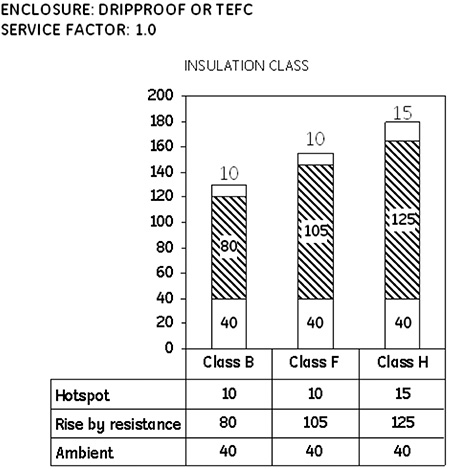

An industry rule of thumb states that for every additional 10 degrees C of winding temperature, the winding life drops by a factor of 2. Conversely, every 10-degree reduction in winding temperature doubles the winding life. A common practice is to specify "Class F insulation with Class B rise." Figure 1 shows the differences in temperature for the three most common insulation systems used in motors.

Figure 1. Winding temperatures of different insulation classes (Graphics courtesy of GE Power Conversion)

Figure 1. Winding temperatures of different insulation classes (Graphics courtesy of GE Power Conversion)Simply specifying "Class F insulation with Class B rise" gives the user a 25-degree reduction in winding temperature under its limit, which should increase winding life by a factor of 5. If a user specified "Class H insulation with Class B rise," winding life would increase by a factor of 9. This can cover a lot of misapplication issues.

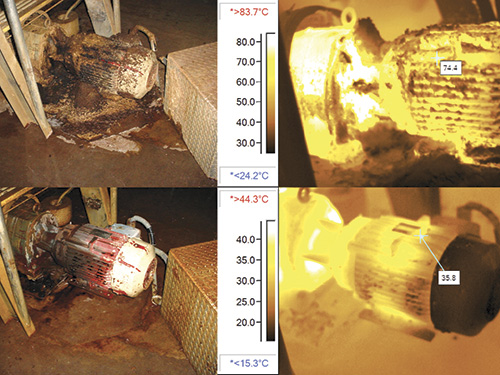

Figure 2 shows a real-world example of what a user can do to improve winding life. In the top two photos, the motor is covered in pulp, and the external surface temperature is 74.4 C. When the motor was cleaned, however, the external surface temperature dropped to 35.8 C. This simple action could result in an increased winding life by a factor of 8, assuming the winding temperature also dropped 40 C.

Figure 2. Temperature measurements of a motor in a paper mill

Figure 2. Temperature measurements of a motor in a paper millService

Motor users can also have some control over service factor. Running a motor into its full service factor of 1.15 normally increases the winding temperature by more than 10 C. Simply running the motor into the service factor can cut the winding life in half.

Motors are usually run into service factor for one of two reasons. First, unforeseen events can happen in the field. This is exactly why service factor exists—to ensure the motor can operate higher than its nameplate power in case of unforeseen circumstances. This should be temporary, and the root cause should be investigated and corrected.

Second, sometimes motors are knowingly sized to run into service factor to reduce the initial cost. A simple exercise will demonstrate why this should be avoided.

Assume that a 75-horsepower (HP) motor costs an end user $6,700. Assume that a 60-HP motor costs an end user $5,700. The actual values are less important than the difference in price.

At first glance, $1,000 seems like a large difference. Assume that a system is being developed that requires a 69-HP load from the motor. A 60-HP motor operating at 1.15 service factor could theoretically drive that load. The National Electrical Manufacturers Association (NEMA) Premium efficiency level for a 60-HP motor operating at 60 HP in a 25 C environment is 95.0 percent. However, the efficiency of this motor could drop by more than an entire NEMA band to 94.4 percent at 1.15 service factor.

This reduction in efficiency is caused by higher temperatures leading to higher resistances in the stator and rotor, resulting in higher I2R losses. A 75-HP motor operating at 75 HP in a 25 C environment is required to be 95.4 percent efficient. At 69 HP, this motor could actually increase in efficiency up to 95.7 percent efficient. Both motors meet the Department of Energy legislation for premium efficient motors. Assuming the motor runs 365 days per year and 24 hours per day and assuming the electricity cost is $0.07 per kilowatt-hour, the 75-HP motor running at 69 HP saves $541 per year compared with the 60-HP motor. In less than two years, only the electricity cost difference will make up for the difference in initial cost.

The temperature rise also has implications. If both motors were designed at "Class B rise at 1.0SF," which is a common specification, the 60-HP motor running at 1.15 service factor will have a temperature rise of approximately 105 C. The 75-HP motor, however, will have a temperature rise of approximately 70 C. If both motors have the same insulation system and the same expected relationship between temperature rise and insulation life, the 75-HP motor will run 35 C cooler than the 60-HP motor. This would result in winding life increasing by a factor of 7.

About 80 percent of the winding rise turns into bearing temperature rise on the drive end bearing of a totally enclosed, fan-cooled (TEFC) motor. In the example, using the 60-HP motor and operating it into service factor means that the bearing will be 28 C hotter than using the 75-HP motor at 70 HP. According to SKF, every 15 C of increased temperature results in a halving of the grease life. This means grease life will decrease by a factor of 4 as a result of using an undersize motor.

Manufacturer & End User Actions

Bearing and winding failures account for almost three-fourths of motor failures. Motor manufacturers can help prevent these failures by using bearing caps and end shields that fully protect bearings from contamination, building motors with low vibration levels, using greases that are commercially available and identifying the grease for the end user. They can also improve motor winding life by using low-temperature rises coupled with high-temperature insulation systems.

End users can increase the bearing and winding lives in their motors by specifying things like "Class F (or H) insulation with Class B rise" and "low vibration levels (0.04 inches per second)." The end user can also ensure that the motor is properly sized to keep the temperature rise down, which will help prevent the system design from forcing the motor to run into its service factor. Together, manufacturers and end users can ensure that they are setting themselves up for success by having a properly designed system that will ensure a reliable and long motor life.