Medium-voltage variable frequency drives (VFDs) have a long lifetime and play a critical role in many industrial manufacturing facilities, making total cost of ownership (TCO) a key factor in purchasing decisions. Medium-voltage VFDs are typically rated between 2.3 and 13.8 kilovolts (kV) and deliver power ranging from 150 kilowatts (kW) to 120 megawatts (MW) at motor speeds from 10 to 15,000 rpm (see Image 1).

Image 1. Medium-voltage VFDs are complex products engineered and built to order for specific applications.

Image 1. Medium-voltage VFDs are complex products engineered and built to order for specific applications.Automation and related components with shorter lives and less critical roles will generally have a TCO that is closely related to the initial purchase price. However, initial purchase price is only one factor that contributes to the TCO for medium-voltage VFDs.

Table 1. Medium-voltage VFD TCO components

Table 1. Medium-voltage VFD TCO componentsIn Table 1, the main TCO factors are listed. The table shows that price is only one of its many components, and in many applications, price is not the most important factor, according to a recent survey conducted by Tritech Marketing Inc. All survey respondents use or specify medium-voltage VFDs, including those from the following industries:

- Mining

- Oil and gas

- Chemical/petrochemical

- Water/wastewater

- Pulp and paper

- Engineering, procurement and construction

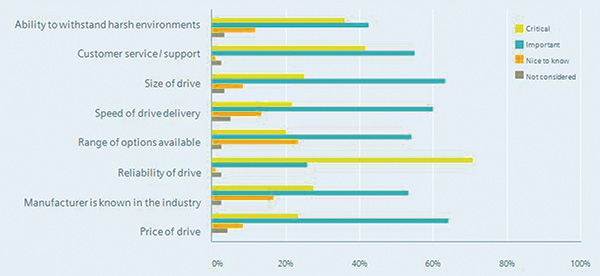

The survey shows that purchasers of medium-voltage VFDs consider several factors when selecting a particular manufacturer and product (see Figure 1).

These factors are listed in order of importance as determined by adding the percentage of respondents who ranked each factor as either critical or important:

- Reliability—97 percent

- Customer service/support—92 percent

- Size of the drive—88 percent

- Speed of delivery—88 percent

- Price—86 percent

- Ability to withstand harsh environments—85 percent

- Manufacturer’s reputation—81 percent

- Range of available options—74 percent

Longevity of the VFD is not listed in the survey but is important. The longer lifespan indirectly, but significantly, contributes to lower TCO.

Figure 1. The leading factors considered by purchasers when selecting medium-voltage VFDs

Figure 1. The leading factors considered by purchasers when selecting medium-voltage VFDsThis two-part series will discuss how factors other than initial purchase price work together to generate a TCO for medium-voltage VFDs. Part One focuses on calculating TCO and the factors that have a significant effect on it. Part Two will discuss the components that make up a highly reliable medium-voltage VFD. Although this series is specific to medium-voltage VFDs, many of the concepts covered are applicable to other assets with long lives that fulfill critical roles in industrial manufacturing facilities.

Calculating TCO

Medium-voltage VFDs have long life cycles, typically measured in decades. Often, a drive will last for the entire life of an application with appropriate maintenance, yet this is often not considered during purchasing. Purchasing decisions are often influenced by the lowest initial price without considering TCO.

Plant operations and maintenance personnel recognize that TCO is critical for optimizing performance for this type of asset. This is especially true for plant managers because they are responsible for maintaining plant efficiency with maximum performance. Operations and maintenance personnel should, therefore, have substantial input about purchase decisions for large, critical capital items such as medium-voltage VFDs.

TCO is calculated by determining the net present value (NPV) of all the costs and savings that result from the purchase, installation and operation of an asset for the duration of its useful life. Some of the key factors in any TCO calculation are price, operating costs and reliability.

NPV normalizes all the costs and savings to the present. The purchase price is a present value, but any future costs and savings must be discounted to correctly calculate their present value, because a dollar saved 10 years from now is worth much less than a dollar saved today.

For non-critical, short-lived assets with low operating costs, the TCO is close to the initial purchase price. For long-lived items—such as a medium-voltage VFD with significant operating costs and a key role in a process—calculating TCO is critical because lower-priced items often have a higher TCO than a higher-priced alternative.

For example, consumers usually buy a short-lived asset (e.g., motor oil for a car) based chiefly on price, but they strongly consider reliability, service and operating costs when buying a car—implicitly, if not explicitly, comparing the TCO among prospective vehicles prior to purchase.

All industrial purchasers will consider TCO to some degree when buying a large capital item with an expected long service life, such as a medium-voltage VFD. Purchasers will calculate TCO in different ways with varying levels of precision, but the basic TCO concepts will hold true in all instances.

When calculating TCO, the initial price is the easiest variable to quantify. Therefore, it often gets the most attention. However, other variables can be just as important, albeit more difficult to estimate at purchase time because they are projected, future values.

For example, greater reliability leads to less downtime and lower maintenance costs, two critical factors in many medium-voltage VFD applications that can be difficult to put into exact numerical terms. Therefore, most purchasers only include estimated numbers for TCO factors other than price and then discount these numbers to the present based on an internal corporate financial metric.

Important factors that contribute directly and indirectly to TCO must be considered when calculating the TCO of competing medium-voltage VFDs. The advantages and disadvantages of different classes of medium-voltage VFDs should also be considered. The first factors to include are reliability, downtime and required maintenance—three closely related elements that work together to have a substantial effect on TCO.

Reliability, Downtime & Maintenance

Not by accident, the survey reported reliability as the No. 1 factor when selecting a drive supplier. Reliability is even more important after all the costs of a drive failure are considered.

For example, using a crude TCO calculation, the cost of a medium-voltage VFD replacement might be only the purchase cost of the replacement drive. However, this does not include the engineering that may be required to make a newer model fit physically or the rewiring necessary to reconnect the newer model. It also does not include the installation cost.

Most important, it does not include the cost of downtime. Downtime costs are usually much greater than even the fully burdened cost of replacing the drive. Unplanned downtime is especially devastating and costly.

If a refinery produces 60,000 barrels per day of refined products (gasoline, diesel or heating oil) and one of the dozen or so main pump drives stop operating unexpectedly, the refinery may lose from 20 to 100 percent of its capacity for as long as that drive is not working. If no shelf spare is available or if engineering must be performed to replace the drive, getting the drives running again may take days or weeks—all while losing hundreds of thousands of dollars per day in stalled production.

A sophisticated and more accurate TCO calculation would include downtime costs, giving much greater weight to drive reliability. One proprietary medium-voltage drive has a proven track record of two-, five- and seven-year campaigns with no unscheduled shutdowns. It is also the only VFD used in nuclear power plants.

Equipment from suppliers with a reputation for reliability are often priced higher than suppliers with newer products that have not been thoroughly tested by years or decades of operation. Many purchasers believe that selecting a well-known, highly reliable drive from a trusted supplier is good insurance against unplanned downtime and, therefore, are willing to pay a higher price upfront if reliability claims can be proven. What creates high reliability in a medium-voltage VFD is discussed in Part Two of this series.