Most people are aware that steel possesses the strength and structural reliability to support a 100-story skyscraper or a mile-long extension bridge. What they may be unaware of, though, is that despite its overall robustness and strength, steel manufacturing can be a delicate process.

One person who is familiar with the intricacies of the steel-making process is Wim Brandsema. Brandsema is director and 50-percent owner of packaged system provider in Emmen, The Netherlands. The manufacturer specializes in creating and supplying complete systems that are used in surface-treating steel, particularly pretreatment applications in the hot-dip galvanizing process. It uses three-dimensional (3-D) computer-modeling technology to create customized systems.

PreTreatment

The pretreatment stage that leads to the actual hot-dip galvanizing of steel is precise:

- A piece of raw steel is pre-treated with a degreaser to remove any oil and grease from its surface.

- Then the steel is “pickled” in a hydrochloric acid bath.

- After pickling, the steel is dipped in flux fluid. The flux fluid ensures that the zinc reacts correctly with the steel.

- The steel is then placed in a melted zinc bath at a temperature of 450 C (842 F). If the previous three steps are not followed properly, the zinc will not adhere to the raw steel, resulting in a substandard product.

- After receiving its hot-zinc bath, the piece of steel is hot-dip galvanized.

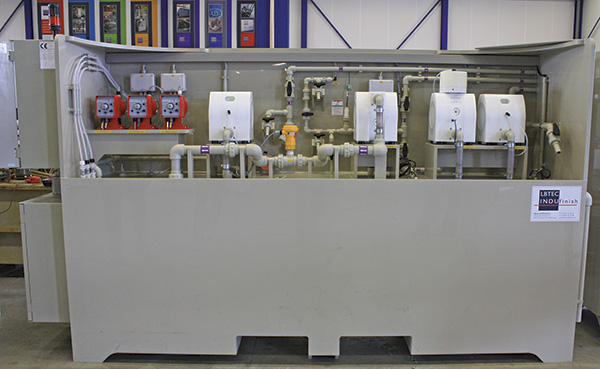

- The manufacturer’s flux-fluid system houses the flux fluid that is used in the pretreatment process. The system consists of four compartments:

- The first contains the flux fluid.

- The second mixes the flux fluid with certain chemicals to obtain the correct pH level.

- The third receives the flux fluid after it has passed through a filter press that ensures that any iron in the flux fluid is collected so that only clean flux fluid exits.

- The fourth gathers the used flux fluid before it is transferred to the flux-cleaning unit and back to the first flux-fluid tank.

Flux-fluid systems are used to pre-treat raw steel before it is introduced to the hot-dip galvanizing process. Solid-body, plastic AODD pumps transfer flux fluid between four distinct holding tanks during the pretreatment process.

Flux-fluid systems are used to pre-treat raw steel before it is introduced to the hot-dip galvanizing process. Solid-body, plastic AODD pumps transfer flux fluid between four distinct holding tanks during the pretreatment process.The heart of the system is the four pumps that keep the flux fluid flowing flawlessly between the four compartments.

“We began producing these units in 2006, and the most important issue is that you have to make sure that the pump is not going to corrode when operated,” said Brandsema. “Flux fluid is very aggressive, so we require a pump that will last at least 10 years. We knew that to manufacture our products, we would need plastic pumps that handle very corrosive fluids like hydrochloric acid. Steel, carbon steel and stainless steel aren’t compatible with these very aggressive fluids, so you need plastics like PE, PP, PVCs and PVDF.”

Benefits of the Chemical-Handling Capabilities

When the manufacturer began developing its flux-fluid systems, it searched for the ideal pump to control the process. Too often, the technology that was chosen for the second stage of the process—in which the chemical solution was introduced to the flux fluid for pH control—fell short in its ability to meet the system’s needs.

“When we first built this system in 2006, we started off with an electric-driven, vertical centrifugal pump for the second stage, but it lasted only six months,” said Erik van der Staaij, sales manager for the manufacturer. “At that point, the engine was rotted away by the chemistry we were pumping, so we needed a very corrosion-resistant solution.”

In the search for a solution, the company’s engineers had to look no further than three other pumps in the system, which were solid-body, plastic, air-operated, double-diaphragm (AODD) pumps.

“We looked at the other three pumps that were mounted on the system at the time,” said van der Staaij. They did not see any corrosion on those pumps, so they mounted another plastic AODD pump for the chemical-solution mixing process.

“We have never seen any leakage from the pump or connections, not on the thread or the pump body itself. Everything sits tight.”

The solid-body, plastic construction makes these pumps ideal for handling the aggressive and corrosive fluids that are used during the hot-dip galvanizing process for steel, including flux fluid and hydrochloric acid.

The solid-body, plastic construction makes these pumps ideal for handling the aggressive and corrosive fluids that are used during the hot-dip galvanizing process for steel, including flux fluid and hydrochloric acid.The pumps are well-suited for dangerous chemical pumping applications in which the pump and system must be reliable. The pumps cannot corrode and do not leak. The solid-body, plastic AODD pumps offer features that make them ideal for handling corrosive fluids. Plastic AODD pumps are positive displacement pumps that have a diaphragm in each of their two pumping chambers. These diaphragms are connected by a shaft so that when the compression stroke takes place in one chamber during the pumping process, the suction stroke takes place simultaneously in the other chamber. This results in efficient, reliable, cost-effective, repeatable operation when handling any corrosive liquid.

Solid-Body Design

The solid-body design is typically constructed of polyethylene (PE), which offers excellent abrasion-resistance. Because of their PE construction, the plastic AODD pumps have higher abrasion-resistance than pumps that are made with polypropylene (PP)—while still having similar chemical-resistance characteristics—and are more durable than stainless-steel pumps.

Solid PE also delivers better sealing, higher static weight, smoother operation and better torque retention than other popular materials of construction. For specific applications, the plastic AODD pumps can also be constructed of PE, PE conductive, polytetrafluoroethylene (PTFE) and PTFE conductive. All the pump’s cylinder valves are constructed of PTFE. The diaphragms may be ethylene propylene diene monomer (EPDM), PTFE/EPDM and nitrile rubber (NBR). The ball valves may be made of EPDM, PTFE, NBR and stainless steel.

Every housing part on the plastic AODD pump is tightened to each other by housing bolts. However, instead of single bolts that press punctually against the housing, all the bolts are tightened against a diaphragm-sized ring on each side of the pump. This results in a more even spreading of the housing-bolt force and an increase in permissible bolt torque, which enhances safety and reliability. An optimized flow pattern reduces the pump’s flow resistance, which results in increased efficiency and lower air consumption.

Other features found in the plastic AODD pumps include:

The flux-fluid manufacturer’s state-of-the-art engineering department is tasked with meeting the specific needs of its end users who need reliable flux-fluid systems that overcome the fluid-handling challenges of the pretreatment of raw steel.

The flux-fluid manufacturer’s state-of-the-art engineering department is tasked with meeting the specific needs of its end users who need reliable flux-fluid systems that overcome the fluid-handling challenges of the pretreatment of raw steel.- A maintenance- and lubrication-free air-control system, which ensures accurate reversal of the main piston

- Optimized flow path for increased energy efficiency

- Internal piston diaphragm technology

- Integral dampeners for constant flow with no need for additional piping

- ATEX conformity for PE conductive and PTFE conductive models

- Variable port configurations

- No drives, rotating parts or shaft seals

- Easy startup

- Metal-free exterior

- Other options: barrier-chamber system for leak prevention, screw-on or flanged pulsation dampener, back-flushing system, stroke counter, diaphragm-monitoring system, and transport cart

Conclusion

Steel may be strong, but its final strength is only derived from the strength of the weakest link in its production chain. Realizing the importance of the pretreatment of steel in the hot-galvanizing process, the manufacturer set out to create a reliable system for end users, and found it in solid-body, plastic AODD pumps. Since 2006, the company has produced more than 50 flux-fluid systems that are used in steel-making applications around the world, all of which use plastic AODD pumps.