Even though most Winter Olympic venues are held in locations that are likely to have white winters, there is no guarantee that Mother Nature will deliver. The host of the Winter Olympics must ensure that plenty of snow is on the ground once the games begin.

Sochi, Russia, the site of the 2014 Olympics, was an unlikely choice for the winter games because it sits on the shores of the Black Sea in a tropical climate. However, a short drive north of Sochi is the Caucasus Mountains—an area well-suited for Alpine Ski events.

Despite the high probability that natural snow would cover the ground during the games, the Sochi 2014 officials could not take any chances. They began taking bids from firms that produce snow when nature does not provide it. This process began before the 2010 games in Vancouver, Canada.

Torrent Engineering of South Bend, Ind., won the contract to design and build the snowmaking system for the Vancouver and Salt Lake City Winter Olympics, and was also selected to develop the systems for Sochi.

Producing Snow

Co-owners of Torrent Engineering, Joe Cousins and Mark Meadows, began the engineering design work in 2008 to ensure that the Rosa Khutor Resort would have enough snow to support the alpine, snowboard, freestyle and cross-country events.

A snowmaking machine used at night the during Sochi Olympics. Courtesy of Torrent Engineering

A snowmaking machine used at night the during Sochi Olympics. Courtesy of Torrent EngineeringLarge amounts of water are needed to make snow, which a natural lake provided. Producing the snow was challenging for two reasons:

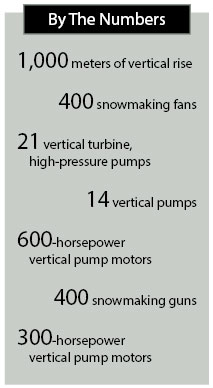

- The requirement to move the water up the mountain from the source—1,000 meters of vertical rise

- Designing a system to provide the amount of snow required

Based on the engineering firm’s success at the Vancouver games, the Sochi committee also awarded it the equipment contract for its system. Cousins and Meadows partnered with SMI Snow Makers of Midland, Mich., with which they had worked on several previous projects. SMI has designed systems for five Winter Olympic sites. For Sochi, it designed a powerful snowmaking system featuring more than 400 snowmaking fans spaced closely together to increase the amount of snow on site.

The key component to this project’s successful operation was the pumping system. The engineering firm worked with a longtime partner, Flowserve Corp. This pump equipment company supplied 21 vertical turbine, high-pressure pumps to pull the water from the lake, push it up the mountain and out to the snow guns.

Powering the Pumps

The motors used to power the pumps were supplied by Nidec Motor Corporation, a motor and controls manufacturer headquartered in St. Louis, Mo., that is a longtime supplier to all three firms. The primary pump station, which was responsible for the initial lift from the lake, was outfitted with 14 vertical pumps, each powered by vertical, solid-shaft motors. These 6-foot tall motors are 5,012-frame, 600-horsepower vertical pump motors.

The Sochi system had two booster stations that were responsible for pumping the water from the main pump house to the 400 fixed snowmaking guns strategically placed on the mountain. Nidec also provided the smaller fan motors for these units. These booster pumps—five at one location, two in another—were equipped with 5,008-frame, 300-horsepower vertical pump motors.

The motors are a vertical design that can be used on normal, medium or high-thrust applications. This application was high-thrust, which occurs when a vertical turbine pump is used. Vertical turbine pumps are typically used for lifting water from wells and up elevations.

This type motor is often used for moving water and wastewater in municipal and industrial applications. Other applications for these motors include water movement in the mining industry, for water treatment and dewatering, and for cooling water circulation in power generation. Big vertical motors are also used for flood control and large-scale irrigation systems.

The motors were designed to work at peak efficiency at high altitudes. Their engineers knew what application questions to ask to design a motor with a long life in the mountainous environment.

Motors that are suitable for use on a vertical turbine pump are the most appropriate for snowmaking because they must move water up a high altitude, resulting in significant thrust on the pump/motor. These vertical motors were specifically designed for this task.

The 5,000-frame vertical motor was updated about eight years ago to a cast iron frame with additional features. It is an updated fabricated frame that has been used for about 50 years, which contributes to the motors’ reliability. Nidec is the only motor company that has ever built a motor specifically for snowmaking. Despite ambient temperatures on the mountain in Sochi that were sometimes less than ideal for snow, the snowmaking system provided substantial snow cover during the games.

Future Winter Olympics

As officials prepare to host the 2018 Winter Olympics in PyeongChang, South Korea, they will also need to consider installing artificial snowmaking systems. Although snow and cold temperatures should not be in short supply in the mountains of the Gangwon-do Province, which experiences average February daytime temperatures in the 30s and nighttime temperatures in the 20s, a snowmaking system will ensure snow if nature does not provide it.