Increased efficiency means more money saved on energy. When competitive bids are evaluated, efficiency is an important factor, especially for high-energy pumps.

A single point of efficiency could mean $5,000 in saved energy per year for a 1,000-horsepower (HP) pump. For a 5,000-HP pump, a single point of efficiency can save about $30,000 in energy costs.

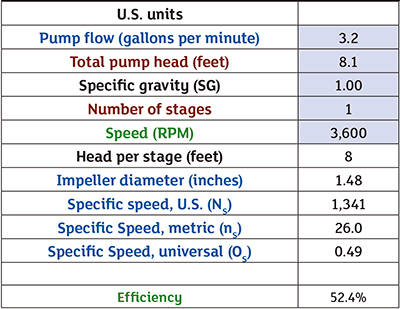

Table 1. The expected efficiency of the pump in the example. (Graphics courtesy of the author)

Table 1. The expected efficiency of the pump in the example. (Graphics courtesy of the author)A better design and better production methods—such as a better surface finish, for example—can result in more efficiency. But do these improvements have a ceiling to the efficiency gains they can provide?

Hydraulic Institute provides charts that can help pump users realize reasonably achievable efficiencies for different types of pumps. The potential efficiency depends on flow, design type (as characterized by the specific speed and surface finish) and other factors. Programs exist to evaluate these commercially achievable average efficiencies.

These values are based on years of testing and represent the efficiency that can be achieved for a typical industrial pump. These charts and programs cover most of the pumps produced in the world, but some exceptions exist.

This column discusses one of these exceptions, for which operators saw a surprisingly low efficiency of the tested pump (see module PVA-7 at pumpingmachinery.com/pump_school/pump_school.htm).

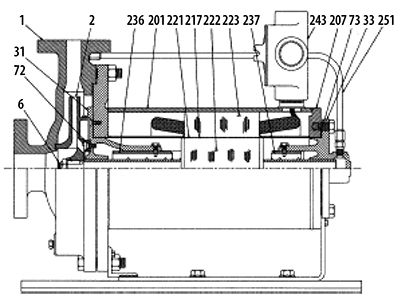

Figure 1

Figure 1As demonstrated in the video, a small single-stage end suction centrifugal pump was tested to show 4.5 percent efficiency. While the low flow of 3.2 gallons per minute and low head of 8.1 feet resulting from a small pump size would not be expected to produce spectacular values of efficiency, 4.5 percent seems excessively low.

A pump efficiency calculator can estimate the expected value of efficiency. Figure 1 shows the results.

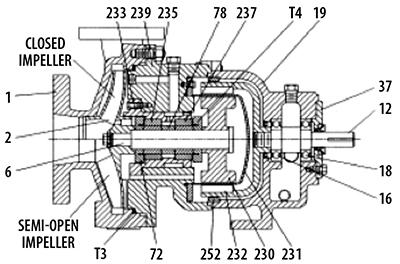

Figure 2

Figure 2The predicted 52.4 percent is not a high efficiency, but it is significantly better than 4.5 percent. Of course, the pump is small, with an impeller size of only 1.48 inches.

At that size, what efficiency would you expect for such a pump? And what is the catch?

I would like to hear from you. The best answer gets you a free ticket to my next Pump School session in January.

Figures 1 and 2 are hints to the puzzle.