Hamilton, Ontario, is one of Canada’s major metropolitan cities. The area’s wastewater treatment plants serve more than 500,000 Hamilton residents and the surrounding towns of Dundas, Ancaster, Water Down, Glanbrook and the former city of Stoney Creek. The treatment plants handle large volumes of sanitary and combined wastewater sewage, placing sizable demands on the pumping equipment.

Plant Details

Woodward Avenue Wastewater Treatment Plant began operations in 1964 and currently processes an average of 108 million gallons (409 million liters) per day. At peak capacity, the plant handles more than 158 million gallons (600 million liters) per day.

The facility’s equipment paid a heavy toll to meet its processing demands. The highly abrasive nature of the water and sludge had heavily damaged the nitrile stators in the plant’s progressing cavity pumps.

When fitted with an appropriate stator, a progressing cavity pump is ideally suited to handle sewage. The progressing cavity action transfers pumped media smoothly and continuously.

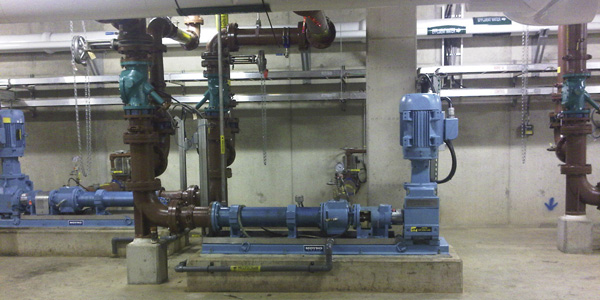

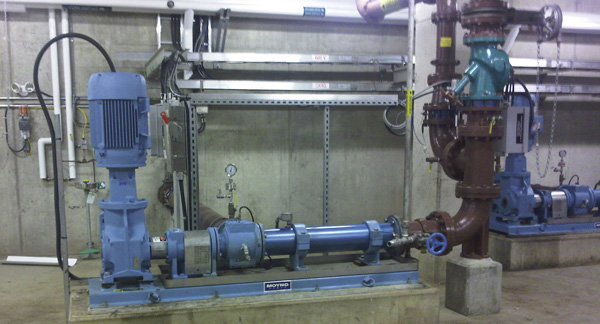

The urethane stators in the plant’s progressing cavity pumps outlasted their original nitrile predecessors by more than 10 times. (Images courtesy of National Oilwell Varco)

The urethane stators in the plant’s progressing cavity pumps outlasted their original nitrile predecessors by more than 10 times. (Images courtesy of National Oilwell Varco)However, Woodward Avenue’s corrosive sludge significantly reduced the working life cycles for the plant’s stators. Maintaining and replacing the stator increasingly cost the plant time and money. Finding an alternative solution quickly became a priority.

Protecting the Local Environment

The reliable treatment of Hamilton’s wastewater plays a vital role in maintaining the quality of the surrounding area, particularly Hamilton Harbor and its ecosystem. Windermere Basin, which is located on the mouth of Red Hill Creek at the eastern end of Hamilton Harbor, has been significantly affected by human activity within the ecosystem.

City authorities tested an alternative stator solution that would withstand the rigors of their sludge treatment. Careful analysis of the sludge characteristics, flow patterns and operational demands of the treatment plant determined the correct elastomer for the new high-performance stator. A recently developed elastomer expanded the stator’s reliability and working life, cutting maintenance time and costs at the Hamilton plant.

Pump failures from prolonged contact with the highly abrasive sludge pushed city officials toward the development of a new urethane stator.

Pump failures from prolonged contact with the highly abrasive sludge pushed city officials toward the development of a new urethane stator.From Nitrile to Urethane

The switch to urethane from the original nitrile stator material proved to be a key factor in the creation of the replacement stator. The urethane elastomers provide better mechanical strength and higher tear resistance than typical nitrile compounds. After successful testing in accordance with the appropriate American Society for Testing & Materials D2000 standards, urethane replacement stators were manufactured and installed at the plant.

The new urethane stators dramatically exceeded project leaders’ expectations. The first replacement stator outlasted its original nitrile predecessor by more than 10 times.

The treatment plant authorities ordered five additional replacement urethane stators for their pumps. As Hamilton expands, these urethane stators will continue to lower maintenance costs and reduce downtime.

Urethane elastomers are available in several versions depending on the application. All versions resist wear in abrasive conditions.

However, certain elastomer varieties are more commonly used in municipal or industrial applications. Others use Food and Drug Administration-approved materials to meet the hygienic needs of the food industry.

Healthier Ecosystems

The urethane stator delivered additional benefits. By enhancing performance in the area’s broader wastewater treatment system, a wider project was designed to improve overall conditions in the Windermere basin. The project transformed a body of poor-quality water with limited ecodiversity into a healthy and diverse Great Lakes coastal wetland.

The project created a new wetland area and constructed hydraulic controls, fish way, power building, islands and containment dikes. The effectiveness of these additions relied on the sustainable performance of the sewage treatment system.

This new, large-scale habitat now supports greater populations of aquatic and bird species in the cleaned Windermere basin. The basin also enhances the landscape and provides leisure benefits to the residents in Hamilton’s industrialized east end.

Representatives from the governments of Canada and Ontario and the city of Hamilton affirmed their commitment to improving the public health and quality of life in the area. Urethane stators and other wastewater treatment advancements are pushing the envelope of what municipalities can do to handle their sewage safely and efficiently. Investing in local efforts and engineering outside the box can uplift an entire ecosystem and improve the quality of life for every resident.