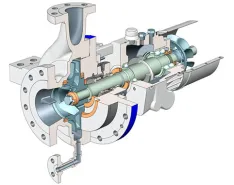

Two types of technology function best in challenging sealing environments.

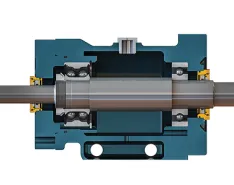

Bearings

White Paper

Optimized bearing design extends pump uptime while lowering running costs

Sponsored by

White Paper

See how optimized bearing specification more than tripled pump uptime

Sponsored by

Yes, friction losses due to bearings can be calculated.

Magnetic drive pumps can suffer damage if not properly lubricated.

Sponsored Video

Bearing and wear ring advances for vertical pumps

Sponsored by

Consider additional options outside of the bearing housing to improve reliability and reduce operating costs.

How to increase longevity and prevent premature failure.

Acceleration transducers (accelerometers) are typically used to measure vibration on stationary components.

The proper grease should be chosen based on factors such as moisture, bearing load, speed, temperature and shaft orientation.

Webinar

This webinar will reveal an often overlooked key bearing variable that can make a difference in your pumping system.

Sponsored by

Consider mechanical seals, gland packed seals and lip seals.

Ryan Ossmann, repair operations manager at Jenkins Electric joins the podcast to talk bearings.

Learn how to determine if oil mist is best for specific applications and when problems are caused by human error.

Basic training for selecting, installing and maintaining bearings.

Hydraulic Institute answers question on best method to see if your bearing is failing

Installation techniques and tips for choosing the best material grade.

Hydraulic Institute answers questions on rolling element bearings and grease as a lubricant.

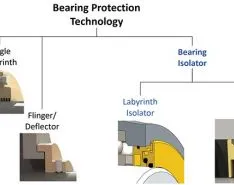

Bearing seals and isolators can eliminate leaks and contaminants

These bearings use sliding motion and a thin film of oil to provide theoretically infinite life.

Calculate and optimize clearance to lower vibration and running noise.