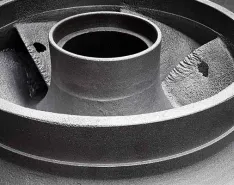

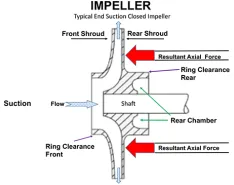

Impellers

Major vibration problems, design flaws contributed to pumps’ fallibility.

Some equipment may run at higher speeds and require a better balance grade to meet vibration standards.

There are several options available to draw water from existing natural resources.

Understand how to achieve the best NPSH performance.

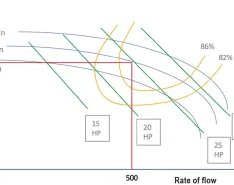

Highlighting oversized or undersized motors could lead to large savings.

Solutions to avoid cavitation and fatigue due to operational and design issues.

High unbalance of a rotating component such as an impeller may result in unacceptable vibration.

Stagnant water may lead to severe corrosion of cast iron impellers and casings.

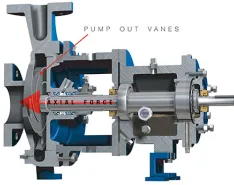

The second installment of Jim Elsey discussing how the impeller affects axial thrust and stuffing box pressure.

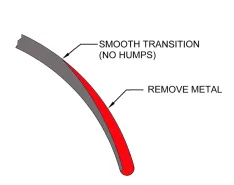

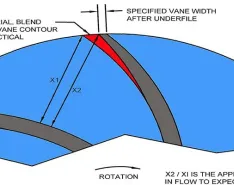

Use these methods to correctly trim an impeller or underfile discharge vanes.

White Paper

Learn the 4 main problems which directly relate to premature bearing and seal failure in this white paper.

Sponsored by

How to extend the life of second-stage impellers and eliminate inlet vane cracking.

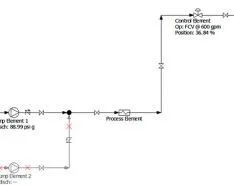

Webinar

Learn about the effect of trimming the impeller on pump efficiency and power usage

Sponsored by

Suspended granite in water required creative solutions for nuclear plant equipment.