Tips to help prevent costly downtime and unexpected failures.

maintenance

Leveraging condition monitoring technology may revolutionize maintenance in the water industry.

Design, maintenance and installation regulations help make sure these pumps are operating properly.

How advanced signal processing can provide machinery health insights.

Choosing the right materials is especially critical in water applications that affect the public.

Guest columnist Michael Key on how implications of reliability extend beyond just the loss of production while the pump is out of service.

White Paper

Discover how insertion valves can help overcome common issues with aging water infrastructures.

Sponsored by

Zach Nepa of SEPCO discusses the basics and maintenance of air seals.

Hydraulic Institutes addresses maintenance strategies for use on pumps.

Understand common failure causes and how to avoid them.

This architecture could help a chemical processing plant experience greater productivity and efficiency with cost savings.

This was the second Turbomachinery & Pump Symposia since the onset of COVID-19.

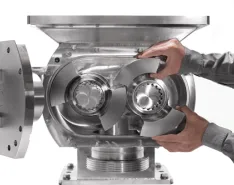

This equipment better fit filter press’ existing footprint and required less maintenance.

Major vibration problems, design flaws contributed to pumps’ fallibility.

Advantages can include cost savings, extra floor space, reduced maintenance and more.

A digital twin can help to solve problems before they occur, increase efficiency and more.

Maintenance tips for helical gear pumps, AODD pumps and skids to keep them running longer.

Avoiding leakage can be important in any application.