Training and education through lubrication audits can help organizations achieve potential.

Maintenance Minders

How to avoid product loss, leaks and downtime.

Microbial growth is most prevalent in a dormant system.

Avoiding leakage can be important in any application.

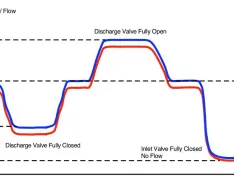

Adjust the scaling factor to receive an accurate flow rate.

Jet aerators eliminate need for a separate mixer for anoxic mixing.

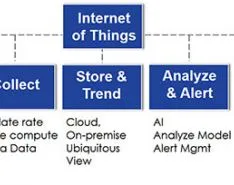

Remote monitoring features enable maintenance teams to track asset health from afar.

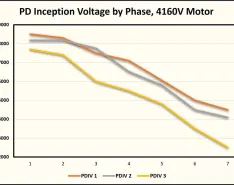

The usage of current alone could lead to incorrect results.

Static motor testing can provide warnings of problems before it is too late.

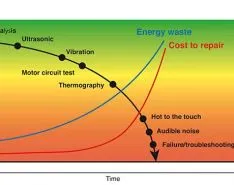

Build a solid condition-based reliability program with this proven best practice.

Why you should design with caution and keep efficiency in mind.

Defining how a mechanical seal will be used and its environment is critical for optimal operation and life.

Best practices help teams tackle repairs in a timely manner.

Understand calculations and specifications.

Service-oriented drives work to reduce energy usage.

Learn the steps to get consistent value from predictive maintenance programs.

This approach focuses on ensuring inherent reliability.

Maximize CMMS functionality with integrated data

Maintenance strategies for efficient installed assets

Users who need dependability and greater depth capabilities may find their answer.