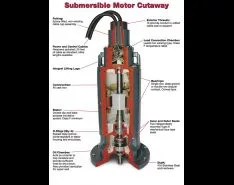

The construction, seals and protective monitoring contribute to the motor’s ability to operate in and under water.

March 2014

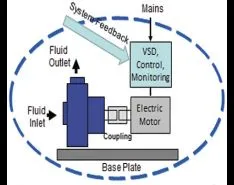

Correctly selecting and installing the ideal component provides significant health, environmental and economic benefits.

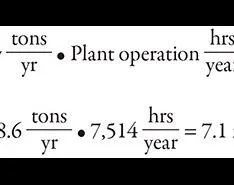

A software simulation tool and detailed engineering analysis procedure are needed for

problem solving.

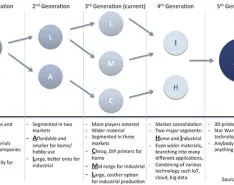

While it is still a relatively new technology, the future of 3-D printing looks bright.

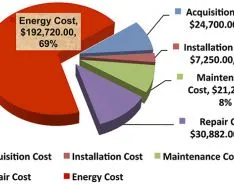

The cost of aftermarket pump upgrades are minimal compared to the cost of downtime and repairs.

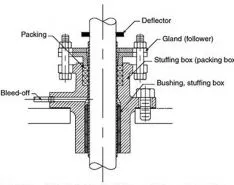

This equipment eliminated a SAG copper mill gearbox’s maintenance issues resulting from contact lip seals that had a short and unreliable service life.

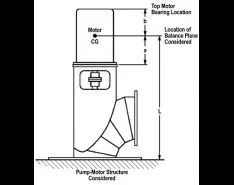

Use a mathematical model that estimates vibration at the top bearing of a motor used on a vertical, wet-pit, column type pump.

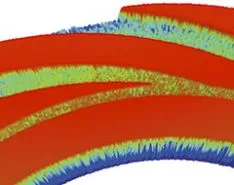

A slurry pump hydraulic lab performs tests which can lead to improvements in pump design for reduced impact wear effects.

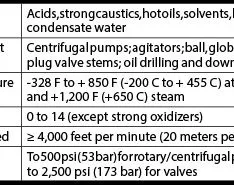

There are many indications that end users should not use a valve for flow control—or at least not to extremes.

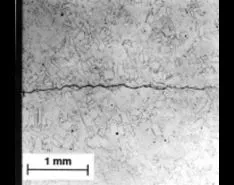

Vibration changes can indicate cracks in pump rotating components, which can cause severe malfunction and failure.

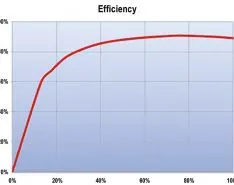

Pump manufacturers should prepare for the changes that the impending DOE pump efficiency regulations will bring, including possible design improvements.

Inspections can identify undetected issues to prevent sanitary sewer overflows and the fines that can accompany them.

Manufacturers and end users should explore their options and see if they can benefit from this technology.

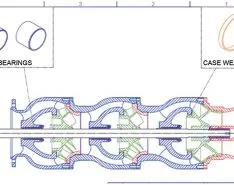

Mapping and testing ensure proper fit and function of replacement parts.