It commonly occurs in liquid piping systems but may not be noticed in cases where the transient pressure wave is less notable

Piping

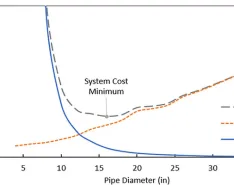

No longer will deadline-driven compromise limit a hydraulic design’s potential.

This practice can ensure safety and reliability of piping systems.

No longer will deadline-driven compromise limit a hydraulic design’s potential.

The restrained styles restrain, or better manage, the pressure thrust forces within the piping system.

Learn how this alternative to metallics can boost your system.

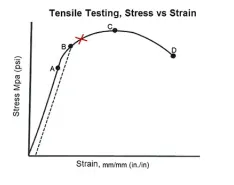

The testing characteristics of ductile and brittle bolting materials.

Why you should worry about water hammer, the damage it can do and how to fix it

Learn what can happen when this component fails

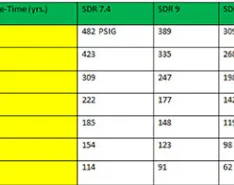

Consider chemicals, temperature, pressure, expansion and more.

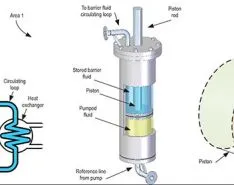

Methods for pressurized seal systems

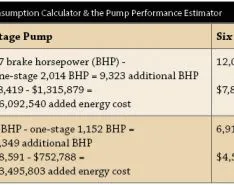

This method of updating can save on piping and other system costs.

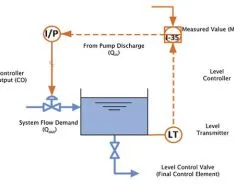

What is the ideal pump for this situation?

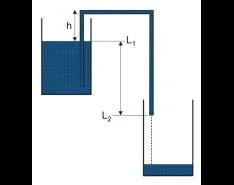

The siphon is an example of a natural and extremely simple machine that we take advantage of daily.

These valves can alleviate a variety of pump system issues.