What can you do to extend the life of this component in the world of industrial rotating equipment?

Seals

White Paper

Find the right O-ring, gasket or seal for your hydraulic application.

Sponsored by

Learn how different metals react, and how corrosion inhibitors can help avoid downtime.

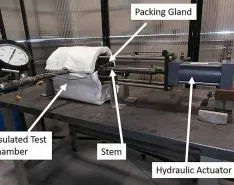

Consider mechanical seals, gland packed seals and lip seals.

The conductivity probe and float switch are the top sensors used.

Defining how a mechanical seal will be used and its environment is critical for optimal operation and life.

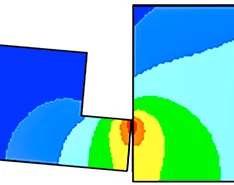

Extra energy transmitted can produce larger sealing stress on the gasket.

Strong oxidizers can damage metal, causing pitting or rust and creating possible safety concerns.

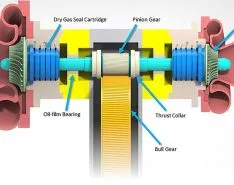

Understand implications involved with using gas film seals in this application.

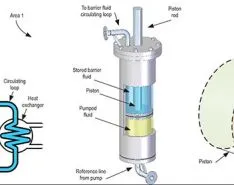

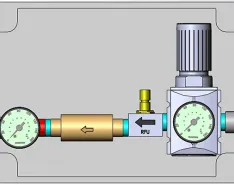

Methods for pressurized seal systems

Rigorous temperature, pressure and exposure conditions must be met.

Keep facilities up and running with simple, proven solutions for these critical assets.

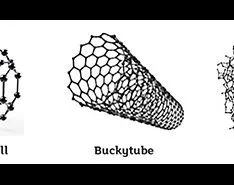

Elastomeric polymer materials provide mechanical strength and self-lubricating properties required in challenging settings.

LPS technology uses static field of injectable sealant and separate air flush.

Consider updating to bearing protectors and cartridge seals.

Seal failure is often a symptom of an underlying problem within the pump.

A seal manufacturer addresses common end user confusion and offers a crash course.

Use these best practices to get the most from component parts