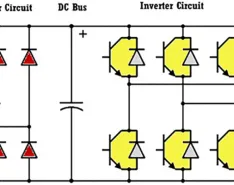

How this technology compares to conventional VFDs.

variable frequency drive (VFD)

Webinar

In this webinar you will learn how to improve your savings and increase them by 10% to 15% over what you are currently achieving.

Sponsored by

De-energized and energized motor testing are techniques used to spark a VFD’s performance.

Commonly, energy consumption and efficiency are referred to interchangeably with pumps.

How VFDs can play a big part in pump system optimization.

These motor systems can run at a synchronous speed, providing improved hydraulic performance.

White Paper

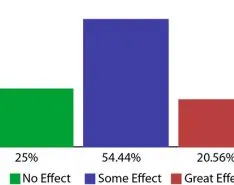

Understanding which parameter settings are most often programmed by VFD installers.

Sponsored by

Users have opportunities to improve efficiency and maximize life cycle with smarter drives.

Remote monitoring features enable maintenance teams to track asset health from afar.

White Paper

Long-term VFD care and restarting electrical equipment after a long shutdown

Sponsored by

White Paper

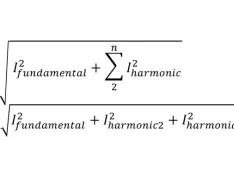

Learn how to limit impacts of non-linear loads and harmonics in this white paper.

Sponsored by

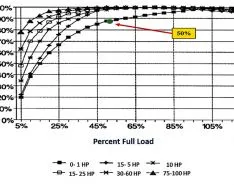

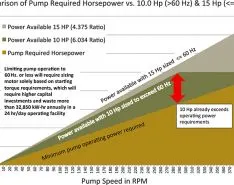

The adjustable flow method changes the flow curve and drastically reduces power requirements.

The study will give industry stakeholders a better understanding of the marketplace and help them become more globally competitive.

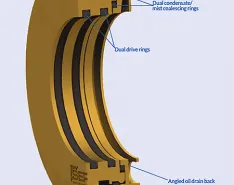

Evaluate the application before installation to ensure a long-lasting, productive and efficient pump.

This technology provides long service life and reliability for variable speed applications.

Facilities predominantly using these drives may face concern from power utility companies.

There are numerous factors to consider to ensure the best performance with this technology.

An influent pump station in Washington incorporated control technology that improved system efficiency and energy savings.

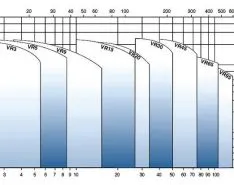

The changing landscape of hydraulic drives is leading many fluid power specialists to quickly adapt to VSDs.

Users should consider system changes to comply with the new EISA standard.