Construction, contaminants and choosing the right bearings can all affect an aerator motor.

Motors

Motors are the most common source of power used by pumping systems. This technology is heavily regulated. Pumps by themselves are not variable speed, an option that many systems need to operate with peaks and ebbs during the run cycle, such as power generation. The addition of a variable frequency drive (VFD) gives it that capability.

Motors are delivering more value to pump OEMs with integrated VFDs and through more connectivity.

Smart variable speed drives offer an efficient and cost-effective method of prevention.

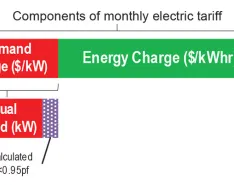

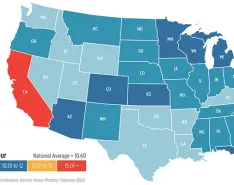

Poor power factor can lead to inefficiencies at wastewater treatment plants.

These motor systems can run at a synchronous speed, providing improved hydraulic performance.

As nonflushable wipes become more of a nuisance, anti-clogging technology steps in.

Ensure the right solution is specified when looking for plugs and receptacles for motor applications.

Emerging technologies, frame sizes part of motor hot topics at conference.

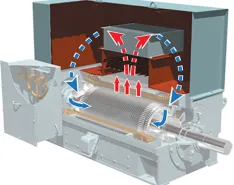

Consider advantages and disadvantages for enclosures of motors at 3,000 horsepower or higher.

Users have opportunities to improve efficiency and maximize life cycle with smarter drives.

Understand challenges and common pitfalls in sourcing electric motors for industrial applications, and find a more straightforward path.

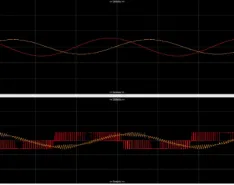

How wide-bandgap transistors are making waves in the industry.

New product design requirements may make some motors obsolete.

In part two of this two part series, Jim Elsey discusses potential issues with variable frequency drives.

Among these factors are humidity, ambient temperature, elevation, sun load and more.

Learn how permanent magnet motor technology can maximize efficiency and reduce operational costs in pumping systems.

These motors are environmentally responsible and result in lower energy costs for users.

Energy-efficient VFDs are vital to meet the new regulatory standards.

These next-generation synchronous reluctance motors can improve system design and performance.

Growth opportunities exist in China; U.S. and Germany emerge as lucrative markets.

Pandemic offers valuable perspectives for other disasters such as hurricanes and storm surges.

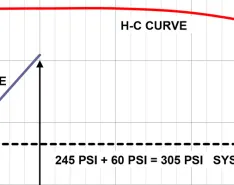

Determining actual water flow and installing a VFD can maximize stations used in high-rise buildings.