Learn the basics of making a pattern using this technology.

Pumps

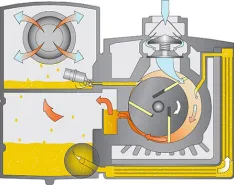

Columnist Jim Elsey on the common issues found on the suction side of the pump.

It has been a complicated 12 years since the Keystone XL project was first proposed.

While the industry took a beating in 2020, look for new technologies to drive growth in the future.

Sensors help with predictive maintenance and warding off overcurrent and undercurrent.

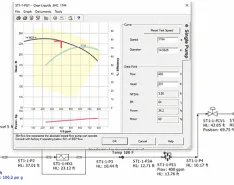

High unbalance of a rotating component such as an impeller may result in unacceptable vibration.

The frequency of instrument recalibration depends on usage and the design of the equipment.

Understand how standards apply to certain metals.

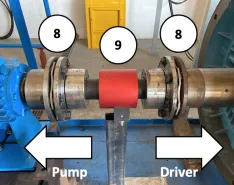

The repair plan implemented for more than 20 pump trains at a large Texas oil refinery.

Why elements of this technology are already providing insights into the operation of physical systems

Wall Street pump & valve industry watch for April 2021

Operating costs play a key role in the decision.

Nongalling materials can survive extended dry-run episodes.

Filters can only be efficient and effective when proper maintenance is completed.

Smart pumps and monitoring can help users maintain a regular maintenance schedule.

Aftermarket services help extend MTBR from three to 10 years.

John Crane experts explain how the industry was impacted from a reliability perspective, and more.

Adding better components instead of returning to as-before status can extend pump life.

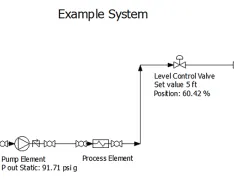

Hydraulic Institute answers this challenging question for a pump system.