Boiler feed pump application example shows increased reliability, low maintenance cost and energy savings.

Pumps

Jannik Röben is CIRCOR International’s senior director of marketing and strategy, industrial pumps.

The following standards and associated tests apply to submersible pumps

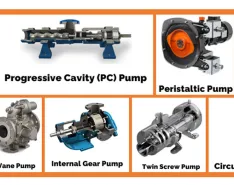

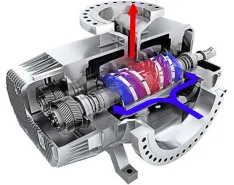

Knowing when to choose a positive displacement or centrifugal pump is critical.

Huck, a recent 10 to Watch selection, also answers questions about his time in the industry

Twist is Manager, Gas Seals, Research & Development for John Crane.

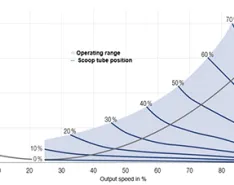

Preventing power loss is essential to operational efficiency.

There are two main types of submersible rotodynamic pumps.

Exploration activity has been up and down this year.

This architecture could help a chemical processing plant experience greater productivity and efficiency with cost savings.

Chemical processing plant was making frequent repairs following bearing failures.

Effective wastewater treatment is critical to the health of ecosystems.

Abhijeet Jain of Atlas Copco discusses why sizing is important, calculations and more.

Select the right pump to comply with the change to fuel oils.

Jim Huck has developed into a road warrior for Industrial Flow Solutions.

Ordinary variable frequency drives can generate harmonics with potential consequences.

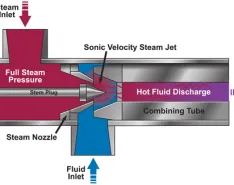

DSI heaters can be regulated as fast and precisely as the control loop can measure and respond to changes in temperature.

The employment index fell back into contraction territory.

Hydraulic Institute provides the basics on the most common pumps.

Training and education through lubrication audits can help organizations achieve potential.