Pumps & Systems, December 2008

Q.

Our office building has a pump room in the basement, which causes sufficient noise to be bothersome to the people in the office above it. What can be done to reduce the noise?

A.

It is assumed you are referring to centrifugal pumps, which are circulating water to heating and air conditioning units and/or supply water booster pumps. Such pumps are usually not noisy, but could be heard in a quiet office environment. Several steps can be taken to reduce noise.

The most obvious is the installation of sound absorbent material in the ceiling above the pumps or the construction of a sound absorbing enclosure surrounding the pumps. Such enclosures must allow for the circulation of air to keep the motors cool. In addition, the piping should be interrupted with a flexible elastomeric coupling to minimize piping born noise.

Control valves in the system can also be the source of noise. Some valve types are noisier than others and can be replaced with quieter designs, if necessary.

Regarding the pump design, the interaction of the impeller passing the volute tongue or cutwater typically generates the most noise. Cutting back the volute tongue or reducing the impeller outside diameter will reduce noise, but these actions will also affect pump performance. Consult the manufacturer before attempting these or any other pump modifications.

Replacing the pumps with slower speed designs may be necessary.

Q.

Can rotary type pumps be used to pump slurries? If so, are there any special cautions?

A.

Rotary pumps may be used for in-plant process and pipeline transfer of slurries when metered flow, medium-to-high discharge pressures are required. Since volumetric and mechanical efficiency are normally dependant on the clearances between the pumping elements of a rotary pump, take care in the selection and application of the pump in slurry service. Slurries containing hard particles can cause abrasive wear in rotary pumps.

The concentration of solids generally has the greatest effect on fluid characteristics of the mixture. A range of 5 to 15 percent by weight of paper stock slurry goes through three different stages of fluidity or shear characteristic.

The size and general shape of the solids in a slurry normally govern whether a particular rotary pump configuration and/or clearances can be used. Usually the clearances must be greater than the particle size. A clearance provision of greater than the maximum particle size for handling hard or fibrous particles is necessary in many rotary pump configurations to prevent binding, wedging and severe wear. This clearance, if greater than normal design clearances, could permit greater slip within the pump and thus should be evaluated for the range of slurry handled.

The hardness of solids greatly influences the wear rate of the rotary pump, since there is close relative motion of surfaces at rotor tip or flank velocity. The range of hardness is from soft solids (such as polymer chains of lubricating quality) to fibrous products (which, though generally soft, may carry hard particles) to very hard irregular particles (such as sand and carbon).

The settling rate and characteristics are the critical factors governing a system handling a water slurry in which the solids have a much higher specific gravity than the carrier liquid. Coarse solids with high settling rate are carried in a rotary pump with many precautions to prevent bridging, draining and squeeze-out.

Regardless of the type of rotary pump used for abrasive slurries, pump speeds should always be reduced well below those for nonabrasive fluid applications. Speed directly affects product shear and the relative velocity of solids to the pump housing and rotor.

For more information on this subject, see the Hydraulic Institute Standard ANSI/HI 3.1-3.5 Rotary Pumps for Nomenclature, Definitions, Application and Operation.

Q.

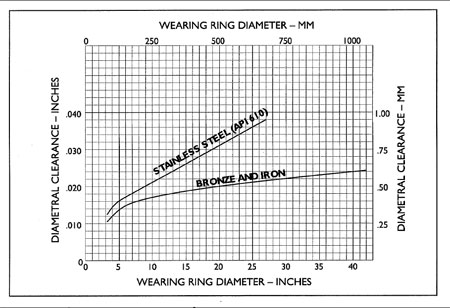

As part of our pump-monitoring program, we measure the diametral clearance of the impeller wearing rings. How do we know the maximum clearance that indicates the wearing ring clearance needs to be renewed? In addition, what is the acceptable clearance value when the rings are renewed?

A.

In addition to measuring wearing ring clearance, pump total head and rate of flow should also be measured. Excessive clearance will reduce total head developed by the pump, and the rate of flow will decrease or the control valve will open further. Measuring the control valve position is also a good monitoring practice as long as the system curve remains the same.

It is normal for wearing rings to "wear." The amount and pattern depends on the liquid being pumped, the presence and size of abrasive particles, liquid viscosity, the pump total head, pump speed and the wear-resisting properties of the rings.

When the total head and/or rate of flow become marginal, the wearing ring clearance must be renewed. The design clearance can be obtained from the manufacturer, or by using Figure 1 as a guide.