Editor's Note: This is the second in a series of five articles based on the Hydraulic Institute's new Positive Displacement (PD) Pumps: Fundamentals, Design and Applications e-Learning course. To read the previous article, click here. To read the next article in the series, click here.

Positive displacement (PD) pumps are used in a myriad of applications across multiple industries. Users have found them to be the solution to many specific pumping challenges; however, due to their size, simplicity and ruggedness, they often are not as well understood as other pump types.

Technologies within the extensive positive displacement family cover a broad range of horsepower, fluid and pressure applications. These products merit increased consideration in a user's pump selection process. To assist pump users with a proper understanding of definitions, applications, installation, operation, maintenance and testing procedures, the Hydraulic Institute publishes ten ANSI/HI Standards covering PD pumps including: Air Operated, Controlled Volume Metering, Reciprocating and Rotary.

ANSI/HI standards perform a vital function in pump industry commerce and serve important roles in minimizing misunderstandings in the marketplace. The Hydraulic Institute has extended its mission to include the development of a pump knowledge and education portfolio in response to member and pump user needs. Among the first key elements are a re-launch of the Centrifugal Pump e-Learning course and the development of a new Positive Displacement Pump course covering fundamentals, design and applications.

Last month, we provided an overview of the curriculum and an overview of positive displacement pumps, as well as the 12 benefits of PD pumps.

This installment will focus on "Positive Displacement Pump Hydraulics," which introduces the fundamental physical concepts and fluid properties that affect positive displacement pump selection and operation.

Since many of these properties affect positive displacement pumps differently than centrifugal pumps, it is critical to understand the interaction between the pump and the fluid, and how the operation of positive displacement pumps differs from centrifugal pumps. Without this foundation of fundamental principles, it would be difficult to effectively learn about the myriad of positive displacement pumps (to be presented in the next three articles).

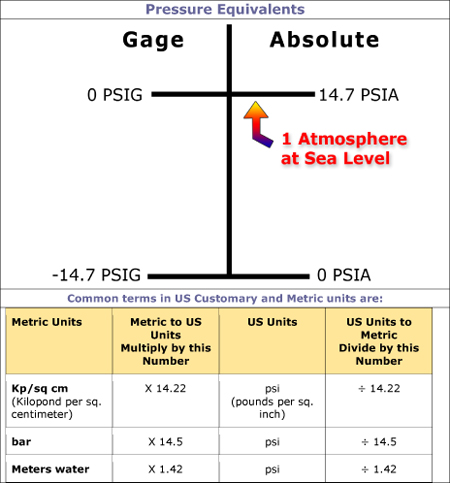

On the most basic level, pumps are used to provide pressure and/or flow so that the pump user can accomplish a specified task. With this premise in mind, note that positive displacement pumps create flow, not pressure. The pressure on the pump is a function of the system's reaction to the delivered flow due to pipe losses, restrictions and elevation changes. See Figure 1 for an explanation of gauge versus absolute pressure; these two different reference points have caused confusion through the years.

Figure 1. Gauge versus Absolute Pressure

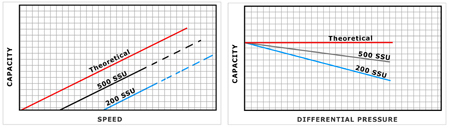

Since positive displacement pumps theoretically generate flow independent of discharge pressure, Figures 2 and 3 show how the delivered flow rate is affected by the differential pressure and speed. This is a fundamental difference between positive displacement pumps and centrifugal pumps. The delivered flow rate is the theoretical flow rate minus the internal slip of the pump. The slip is the internal leakage that occurs in the pump due to clearances, viscosity and differential pressure, and will vary between pump types and applications.

Figures 2 and 3.

Of course, nothing comes for free, and every pump requires a certain amount of power to perform work. The pump input power is comprised of the theoretical liquid horsepower and the internal power losses at the operating point. The theoretical liquid horsepower is the work done to move the theoretical volume of fluid from inlet to outlet pressure and is solely based on the physical dimensions of the pumping elements, the operating speed and the differential pressure. On the other hand, the internal power losses account for the mechanical and viscous losses that occur as the pump operates. It is typical that the mechanical loss is the major component when operating at low viscosities, while the viscous loss is larger at high viscosities. These losses in turn affect the overall efficiency of the pump.

Fluid characteristics play a major role with positive displacement pumps since most of these pumps are used to handle products other than water. The most important fluid property is viscosity, which is the fluid's ability to resist a shearing force, or how easily the fluid will flow. Viscosity affects pump selections due to its impact on operating speed, allowable differential pressure, suction capability and input power. Since viscosity is typically temperature dependent, it is important to know what the viscosity values will be over the entire operating temperature range, from cold start-up to maximum upset condition. Viscosity can be expressed in many different units, the most common being SSU, SSF, centipoises (cP) and centistokes (cSt). Units depend on which viscometer instrument was used to evaluate the different fluids. These values are tabulated in many texts, and several examples are provided in the module (see sidebar for more information).

Along with viscosity, it is essential to understand how a fluid reacts to being pumped. A fluid can have a constant viscosity (at a particular temperature and pressure) regardless of the rate of shear (known as a Newtonian fluid), or the viscosity can vary with the shear rate and shear stress (known as a Non-Newtonian fluid). Non-Newtonian fluids are divided into five types: plastic, pseudo-plastic, dilatant, thixotropic and rheopectic. The first three are time independent since the viscosity is simply a function of the shear stress, while the last two are dependent on both time and shear stress. To accurately determine the viscosity of non-Newtonian fluids, it is usually necessary to take measurements at several points. If the apparent viscosity is not accurate, it can result in an improper pump selection.

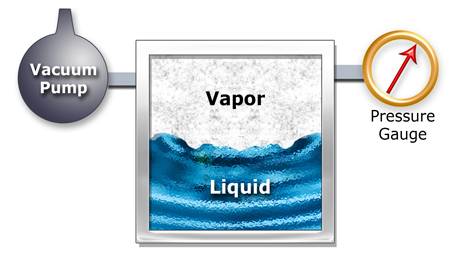

Beyond viscosity, several other fluid characteristics relate to positive displacement pump selection and operation. One of these characteristics is vapor pressure. The vapor pressure is the absolute pressure at which a liquid changes to a gas (see Figure 4). The primary influence of vapor pressure is on the Net Positive Inlet Pressure (NPIP) required for the pump. The NPIP is the absolute pressure above vapor pressure required to get the fluid into the pumping elements. As can be seen with a fixed inlet pressure, the higher the vapor pressure, the less pressure available to get the fluid into the pump.

Figure 4. Vapor pressure at 60-deg F in PSI absolute

Net Positive Inlet Pressure plays a key role in pump selection and system design. Since pumps cannot pull fluid into them, they rely on the difference in pressure between the liquid source and the pump inlet to get the product into the pump. Sufficient pressure must be available at the pump inlet to fill the pumping chambers and prevent gas from being released from the fluid. Therefore, the inlet pressure available must always be greater than the inlet pressure required.

The inlet pressure available is a system characteristic that is determined from the following factors: atmospheric pressure, elevation of the fluid level (above or below the pump inlet), inlet line friction losses, vapor pressure, and in the case of reciprocating pumps, acceleration head. Acceleration head, a unique factor for reciprocating pumps, is the pressure required to accelerate the liquid column at the beginning of each stroke. Depending on the suction line length, average line velocity, pump rotational speed, number of pistons and liquid elasticity, the acceleration head can easily be the largest factor of the available inlet pressure calculation.

The inlet pressure required is a pump characteristic that the manufacturer calculates. It is affected by such factors as pump design, viscosity and speed. Once the available inlet pressure is known, it can be compared to the inlet pressure required by the pump to determine if the pump will operate properly. Sometimes several iterations between the user and supplier are required to select the correct pump.

Once all of the important factors affecting pump selection are understood, hydraulic selection becomes easier. However, other factors external to the pump need to be evaluated to ensure that the entire pump system is properly selected. These factors include environmental conditions such as installation location and electrical requirements, the control philosophy of how the pump will operate, the utilities available and the operating energy requirements.

All of these factors flow into the life cycle costs of a pumping system, which nearly always exceed the initial cost of the machine. The life cycle costs, which can be fully explored in the Hydraulic Institute publication, Pump Life Cycle Costs: A Guide to LCC Analysis for Pumping Systems, are explained in detail and consist of the initial cost plus such items as installation, power, operation, maintenance, downtime and environmental considerations.

This information on PD hydraulics forms the knowledge base for PD pumps (and the HI e-Learning course), so users can properly evaluate any pumping system and select the best technological solution based on the entire spectrum of process conditions and system limitations.

In future issues, look for articles devoted to specific positive displacement pump technologies:

- Rotary Pumps, including: Vane, Rotary Piston, Flexible Member, Lobe, Gear, Circumferential, Piston, Progressing Cavity, Timed Screw, Untimed Screw

- Reciprocating Pumps, including: Power, Direct Acting, Power Diaphragm, Air Operated Double Diaphragm, Air Operated Piston

- Metering Pumps, including: Torque Sources, Drive Mechanisms, Capacity Control, Liquid End Reviews

Pumps & Systems, March 2009