Pumps & Systems, April 2008

In today's upstream and midstream oil and gas environment, screw pumps are playing a larger role in what has traditionally been a centrifugal and reciprocating pump market. This is due in large part to technological innovation by screw pump manufacturers and the industry's need to pump heavier crude oils. Both twin screw and three screw pumps are successfully operating in multiphase, heavy crude oil and crude oil/water emulsion applications.

The oil and gas industry is producing, transporting and refining more unconventional, heavier grades of crude oil from places such as Canada, California, Mexico and South America. Crude oil from these areas is highly viscous, often requiring diluent, steam or other stimulation just to flow the oil from the reservoirs to the pipelines. These nontraditional grades of crude oil are ideally suited for pumping with a screw pump.

The oil and gas industry is producing, transporting and refining more unconventional, heavier grades of crude oil from places such as Canada, California, Mexico and South America. Crude oil from these areas is highly viscous, often requiring diluent, steam or other stimulation just to flow the oil from the reservoirs to the pipelines. These nontraditional grades of crude oil are ideally suited for pumping with a screw pump.

Depending on the actual application, either twin screw or three screw pumps are used in crude oil pipeline services. Three screw pumps are typically found boosting pressure from laterals to the main pipeline, while twin screw pumps are predominantly utilized in the main pipeline boosting stations. The primary advantages of screw pumps include the ability to handle a wide range of viscosities; centrifugals can vapor lock while pumping diluent blended crude oils and become extremely inefficient when pumping crude oils heavier than 250 cSt. Screw pumps have extremely low pulsation, eliminating the need for pulsation dampeners or complicated pipeline support systems required by reciprocating pumps.

Three Screw Pumps

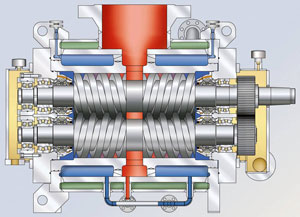

Three screw pump designs are generally capable of flow rates exceeding 1100 gpm and differential pressures up to 1700 psi. The pump consists of three rotors, one power and two driven; one externally lubricated bearing capable of handling thrust loads induced by high inlet pressure; one balanced mechanical seal; a liner; a casing and a bearing/seal housing. The power rotor (coupled to driver) performs the pumping work, while the idlers act to seal off the pumping chambers. The torque is transmitted to the driven rotors by a rolling contact. The pumped fluid creates a barrier between the rotating elements, preventing metal-to-metal contact of the rotating elements. The liquid film also supports the rotors in the liner, eliminating contact between the rotors and the liners.

Three screw pump designs are generally capable of flow rates exceeding 1100 gpm and differential pressures up to 1700 psi. The pump consists of three rotors, one power and two driven; one externally lubricated bearing capable of handling thrust loads induced by high inlet pressure; one balanced mechanical seal; a liner; a casing and a bearing/seal housing. The power rotor (coupled to driver) performs the pumping work, while the idlers act to seal off the pumping chambers. The torque is transmitted to the driven rotors by a rolling contact. The pumped fluid creates a barrier between the rotating elements, preventing metal-to-metal contact of the rotating elements. The liquid film also supports the rotors in the liner, eliminating contact between the rotors and the liners.

As crude oil enters a three screw pump, it fills the suction pumping chamber of the screw set; as the screws turn, crude oil is conveyed from suction to discharge. This positive displacement action simply moves a volume from suction to discharge, as if it were an infinite stroke piston without the need for complicated internal porting and valving.

In most cases, three screw pumps are used in applications where sand and particulate have been removed from the crude oil (i.e. pipeline grade crude oil). However, since some particulate may have survived the crude oil settling process, most pumps are available with alternative liner coatings to prevent premature wear, and the rotors are normally hardened.

Three screw pumps usually boost pipeline lateral pressures to the main pipeline that flows to a refinery or terminal. The main pipelines usually require higher flow rates and pressures, which is best accommodated by large twin screw pumps. Today, twin screw pumps have flow capabilities exceeding 11,500-gpm and differential pressures to 1,400-psi.

Twin Screw Pumps

Twin screw pumps are hydraulically balanced, pulsation free and deliver a given volume from suction to discharge, meeting whatever back pressure the system puts on the pump. The pump has two rotors, one drive and one driven, and relies on the pumped fluid to fill the clearances between the rotors and rotors and liner. The pumped fluid seals the individual pumping chambers of the screw profiles, allowing the pump to maintain prime. In a rigid rotor design, the liquid acts as a sealing mechanism only and does not act as a bearing support for the rotors.

The rotors are supported on both ends by bearings, and torque is transmitted from drive to driven rotor via timing gears. By eliminating rolling contact between rotors, as is the case with three screw pumps, twin screw pumps can handle everything from water to heavy crude oils.

In most designs, the timing gears and bearings are external to the pumped fluid. The timing gears are oil lubricated, while the bearings are lubricated by grease or oil. Depending on differential pressure requirements, the bearing and timing gears may require a forced lube oil system to properly dissipate heat and improve overall component reliability.

Since there are at least four bearings in a twin screw pump, there are four shaft penetrations and four mechanical seals. Seals are available in both single and double seal configurations, depending on the actual service. Single seals are typically used for crude services, while double mechanical seals with a barrier fluid system are also available.

Twin screw pumps are increasingly popular in the midstream market, where their ability to handle high viscosities allows operators to pump colder or use less diluent. This is especially evident in ongoing pipeline projects bringing heavy Canadian crude oil to the American Market.

Twin screw pumps are increasingly popular in the midstream market, where their ability to handle high viscosities allows operators to pump colder or use less diluent. This is especially evident in ongoing pipeline projects bringing heavy Canadian crude oil to the American Market.

Multiphase Applications

The evolution of twin screw pumps has led to their implementation in multiphase applications. Twin screw style pumps dominate the upstream market in multiphase applications due to their operational flexibility and economical installation. Multiphase pumps boost the untreated flow stream produced from oil wells to downstream process or gathering facilities. This means the pumps handle 100 percent liquid to 100 percent gas (with recirculation) and every combination in between. These pumps are packaged for land-based, offshore and subsea applications.

Multiphase pumps are typically found in the following services:

- Lower well head pressure-As reservoirs mature, their natural pressure declines and production decreases. Multiphase pumps are able to boost the flow line pressure, allowing increased production flow rates, while bucking downstream line pressure. By drawing down well head pressure, additional production will occur as the inflow to the production tubing increases.

- Reduced facilities-Rather than separating the gas from the liquids, treating the phases and then compressing and pumping the individual phases, multiphase pumps handle untreated well flow with one piece of equipment. By utilizing one piece of equipment, economic justification is significantly higher for remote single well production and well cluster development with centralized process facilities.

- Flow assurance-Multiphase pumps deliver a constant flow at a given speed regardless of system pressure. By changing the pump speed, operators can optimize the flow rate and inlet pressure, thus boosting total reservoir recovery, improving end of life production and reducing paraffin or hydrate buildup.

Current multiphase pump designs deliver up to 330,000-bpd (total flow) at differential pressures up to 1,200-psi. Given the current trend toward deepwater development, the oil and gas industry has recently identified the need for multiphase pumps capable of flows up to 600,000-bpd (total flow) and differential pressures exceeding 2,400-psi.

Current multiphase pump designs deliver up to 330,000-bpd (total flow) at differential pressures up to 1,200-psi. Given the current trend toward deepwater development, the oil and gas industry has recently identified the need for multiphase pumps capable of flows up to 600,000-bpd (total flow) and differential pressures exceeding 2,400-psi.

The operational flexibility, higher efficiency and robustness of screw pumps make them ideal candidates for an increasing array of applications within the oil and gas industry. Ongoing development of screw pump technology will only broaden their use in multiphase, crude oil, emulsion and produced water services.