Pumps and Systems, March 2009

When you think about it, getting people and businesses to acknowledge the benefits of increasing energy efficiency is an easy sell. Are there any people or companies hoping that their utility bills-heating, water or electricity-continue to go up? No. The hard part is finding the best way to implement these energy efficient improvements.

In the manufacturing sector, energy costs continue to rise, and companies are being asked to improve profitability through greater cost controls. Reducing energy consumption has become a key component in controlling costs at manufacturing facilities as higher energy costs impact every company's and country's bottom line.

Now that the goal has been identified, the time has come to find, develop and implement the best ways to make the manufacturing sector-specifically its pumping systems-as energy-efficient as possible.

The Challenge

As spelled out in Improving Pumping System Performance: A Sourcebook for Industry, a joint effort between the Hydraulic Institute and the U.S. Department of Energy's Energy Efficiency and Renewable Energy (EERE) Program, poor design and improper system operation are at the root of inefficient pumping systems. As rotating equipment and pumps are subject to wear, erosion, cavitation and leakage. These problems can be exacerbated through improper pump selection and operation. If they are not selected or operated properly, pumps can waste enormous amounts of energy, as well as require considerable maintenance.

Selecting the proper pump for each of the myriad operations in a manufacturing facility can be a daunting task. This selection process is further complicated by the fact that many different types of pumps can be applicable for a single operation. When making the final pump choice, several crucial factors may need to be considered: required flow rate, suction and differential pressure, temperature, viscosity, corrosiveness of the liquid being handled, etc. In addition, facility managers too often choose oversized pumps when outfitting systems because they believe such equipment will address future capacity needs. These decisions ignore the added energy costs inherent in operating oversized pumps.

Choosing a pumping system is most often determined by selecting a positive displacement (PD) or centrifugal pump. While the majority of the world's pumping tasks may be performed with centrifugal style pumps, an increasing number of facility managers and operators are becoming aware of the benefits-including energy savings-that are found in pumps that take advantage of sliding vane technology.

By virtue of the inherent energy- and mechanically-efficient designs, positive displacement, sliding vane pumps are uniquely suited to offer managers immediate high-value advantages and solutions in fulfilling energy-saving initiatives. Although the operating principles of PD and centrifugal pumps differ widely, in many cases both designs can be used for the same services. In these "overlap" applications where either PD or centrifugal pumps may be used, choosing positive-displacement technology can result in improved processes, uptime and energy savings. PD pumps outperform their centrifugal rivals in many of them.

Depending on the application, PD pumps may offer:

-

Constant flow relatively independent of changes in system pressure

-

Constant flow relatively independent of changes in pumpage viscosity

-

Ability to pump high viscosity products

-

Ability to handle entrained gases

-

Ability to self-prime

-

Ability to line strip

-

Ability to run dry for short periods

-

Higher efficiency across varying system pressures

Since PD pumps maintain higher efficiencies through a wider range, when considering the overlap where both types of pumps can operate, a PD pump's higher mechanical efficiency may result in greater energy efficiency than a centrifugal pump.

PD pumps offer many operational advantages. In the PD pump family, sliding vane technology is one option.

Possible Solutions

PD pumps pressurize fluid with a collapsing-volume action, essentially moving an amount of fluid equal to the displacement volume of the pump with each shaft rotation. As such, PD pumps have what is called a fixed displacement volume, which means that the flow rates they generate are directly proportional to their speed and the pressures generated are determined by the system's resistance to this flow.

These characteristics make PD pumps appropriate for applications that feature viscous working fluids; systems that require high-pressure; low-flow/high pressure requirements; flows that must be precisely controlled; or when high pumping efficiency is desirable.

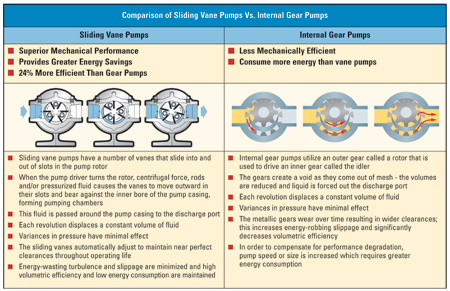

Within the PD pump family, sliding vane and gear pumps are two of the most widely used rotary types.

Gear Pumps

A gear pump uses the meshing of gears to pump fluid by displacement. As the gears rotate, they separate on the intake side of the pump, creating a void, which is filled by the fluid being handled. This fluid is transported by the gears to the discharge side of the pump where the meshing of the gears forces the fluid to exit the pump through the discharge port.

Gear pumps can be further divided into external gear pumps and internal gear pumps. While the pumping action for both is comparable, external gear pumps use two similar rotating gears to mesh whereas the internal gear pump uses a drive, or rotor, gear operating against a smaller internal, or idler, gear.

Because of their style of operation, gear pumps wear as the pump's gears mesh together to move fluid. This constant wear increases the internal pumping clearances in the process, reducing flow capacity and volumetric consistency by increasing the "slip" within the pump (the movement of the fluid being handled opposite of the direction it is being pumped).

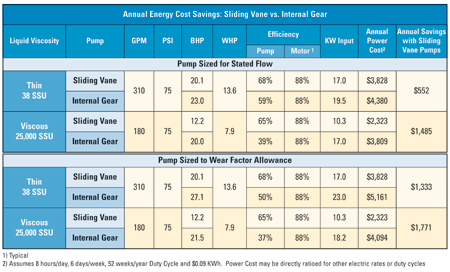

To compensate for these larger clearances, the pump speed or size must be increased, which can increase energy consumption and accelerate pump wear. If these wear conditions go undetected, energy efficiency and performance can degrade before the necessary maintenance is performed (see Figure 1).

Figure 1

As reported in the Hydraulic Institute's "Testing for Pumping System Efficiency" Tip Sheet, "A (gear) pump's efficiency can degrade as much as 10 to 25 percent before it is replaced, according to a study of industrial facilities commissioned by the U.S. Department of Energy, and efficiencies of 50 to 60 percent are quite common. However, because these inefficiencies are not readily apparent, opportunities to save energy by repairing or replacing components and optimizing systems are often overlooked." The degradation of internal clearances is also a trait found in centrifugal pumps, leading to a reduction in operational and energy efficiencies.

Sliding Vane Pumps

Sliding vane pumps operate through the use of a number of vanes that slide into or out of slots in the pump rotor when the pump is rotating. The vanes move outward from the rotor, ride against the inner bore of the pump casing and form pumping chambers. As the rotor revolves, fluid enters the pumping chambers from the suction port. The fluid is transported around the pump casing until it reaches the discharge port where it is forced out into the discharge piping. This type of design virtually eliminates slippage, meaning that the pump's high volumetric efficiency is maintained.

Because the self-adjusting sliding vanes continuously adjust for wear, sliding vane pumps are able to maintain near-original efficiency and capacity throughout the life of the pump. The pump speed does not need to be increased over time, making sliding vane pumps energy-savers (see Figure 2).

If the sliding vanes wear out, or are damaged, replacing them can be quickly accomplished by removing the outboard head assembly, removing the old vanes, inserting new ones and reinstalling the head. The pump can then be put back in operation.

Sliding vane pumps are used in a wide variety of process and transfer applications within numerous markets, such as chemical process, crude oil, refined fuels, biofuels, pharmaceuticals, cosmetics, food processing, health care manufacturing, pulp & paper, wastewater, military, commercial marine, soap & detergents and paint & coatings. These pumps can range in size from 3/4-in ports to 10-in ports with flow rates ranging from 1-gpm (3.8-lpm) to 2,200-gpm (8,328-lpm) with a maximum viscosity of >500,000 SSU (108,000 cP).

Conclusion

Sliding vane technology is used worldwide to reduce energy cost and consumption, and create more efficient pumping systems. Figure 2 compares the performance of sliding vane and gear-pump technology.

Figure 2

This leading-edge technology solves everything from suction, product shear and volumetric-efficiency problems to offering unique benefits such as line-stripping capabilities and metering-all while saving energy. Simply put, sliding vane technology offers numerous advantages to reduce energy consumption and cost without sacrificing performance.