Many methods are used to tighten fasteners. The most common is using a hand or impact wrench and “mechanic’s feel.” The installer tightens the fastener until it feels tight. While this process is acceptable for non-critical applications, it is unacceptable when greater tension accuracy is required.

In more critical situations, the first thought may be to use a torque wrench. However, what torque should be used, and will the required tension be achieved? This “Sealing Sense” is intended to help end users choose the best torque to apply for their applications. It will demonstrate the importance of lubrication and describe procedures that provide the required compressive load on a gasket using torque. It will also identify other important considerations for proper assembly.

A more comprehensive discussion of the entire assembly process for bolted flange joints can be found in ASME Standard PCC-1-2010. Information provided in this “Sealing Sense” is consistent with that document’s guidelines.

A word of caution, torque is not the most accurate way to tension a fastener. The amount of tension achieved from torque is affected by a number of variables. Friction is the most important, and it is difficult to control. High friction results in low tension, and low friction results in high tension. At best, torque tension results will vary in un-lubricated fasteners by +/-25 percent. Using a lubricant can improve this to about +/-15 to 20 percent.

Important Steps

To ensure the appropriate tightening of fasteners, certain steps should be followed:

Determine the tension needed for each fastener.

Choose a fastener size and grade with strength that can provide the required tension without being overloaded.

Calculate the required torque.

Use a calibrated torque wrench.

Apply torque correctly to evenly load all the fasteners.

Use only through hardened washers.

To determine the tension needed on each fastener, establish the total compressive load required for the application. Divide this by the number of fasteners to find the tension needed for each.

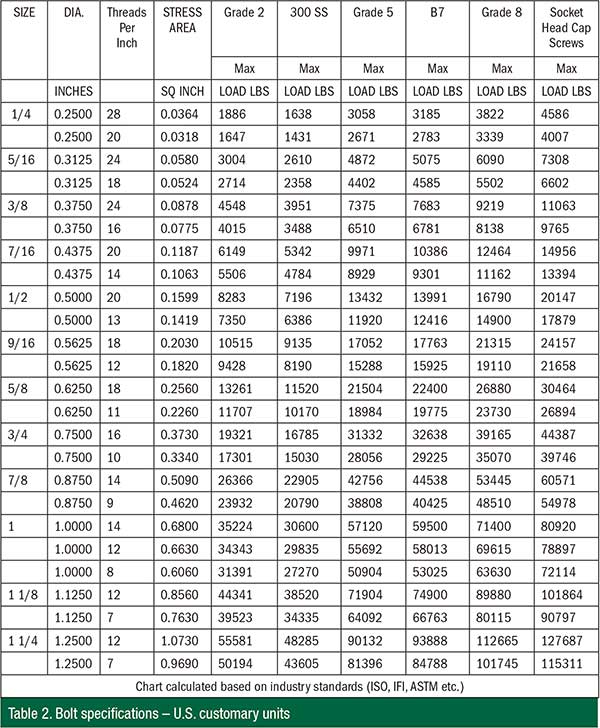

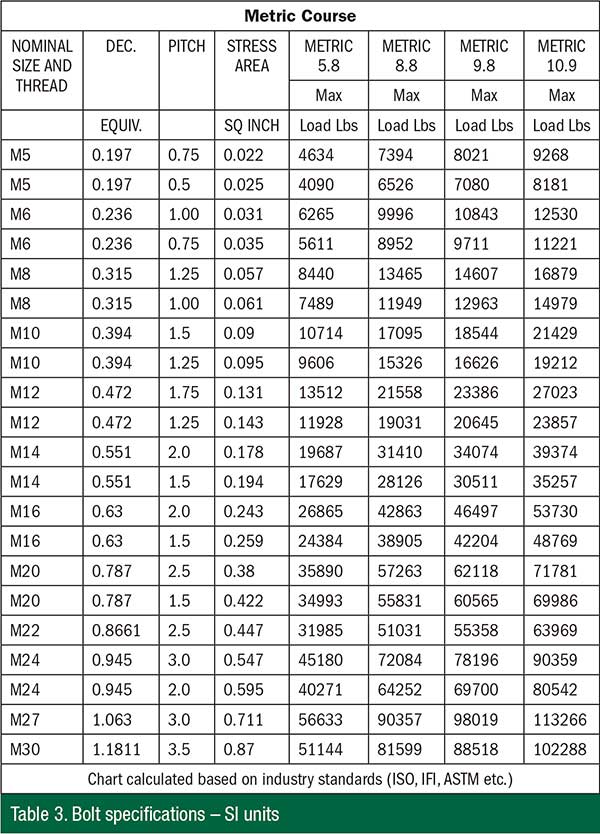

Next, choose the fastener size and grade. In most cases, end users already know the size since the application usually determines the required size. Keep in mind that a fine-threaded fastener of a given diameter is able to tolerate a higher load than a coarse thread of the same size. If a load is needed that is higher than a coarse-threaded fastener has the ability to provide, a fine-threaded fastener of the same grade and size can provide more tension and may be able to meet the need. Tables 2 and 3 list common grades, stress areas and maximum loads permitted using U.S. customary and International System of Units (SI) bolts. Never exceed these loads.

|

| Table 2. Bolt specifications – U.S. customary units |

|

Table 3. Bolt specifications – SI units

How to Calculate Required Torque

A common method of calculating the required target torque uses the formula below:

T = (KDF) / 12

Where:

T = Torque, foot pounds

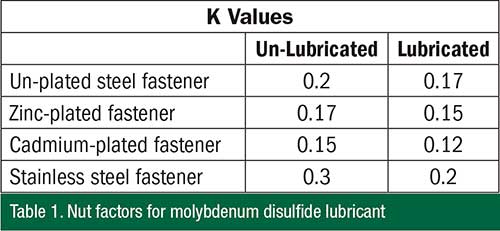

K = Nut factor (torque coefficient resulting from estimated coefficient of friction)

D = Nominal diameter of the bolt, inches

F = Tension, pounds

Dividing by 12 gives foot pounds. If inch pounds units are required, do not divide by 12.

Sample Torque Calculation

This example assumes that four 3/8-16 bolts must provide a total load of 20,000 pounds. Each step for applying the correct tightening should be followed:

Step 1—Tension needed for each fastener: 20,000 / 4 fasteners = 5,000 pounds needed for each fastener.

Step 2—The size is 3/8-16, which is a 3/8-inch nominal diameter fastener with 16 threads per inch. Using Table 2, a 3/8-16, Grade 5 fastener has a maximum load capacity of 6,510 pounds. This fastener is appropriate for this application. For this example, assume it is an un-plated steel fastener.

Step 3—Calculate the torque. This step can be tricky. Since friction variation will cause tension variation, controlling the friction as much as possible is important. Lubricants are used to do this. They must be applied to the threaded surfaces of the bolt, the nut and under the bolt head. Many lubricants are available, and they do not all work the same. Typical brush-on, thread lubricants are not always the best choice. They are intended more for facilitating fastener removal than controlling tightening friction. One of the lubricants often used (when it is permitted) is molybdenum disulfide grease with an extreme pressure (EP) additive. This lubricant is used in this example.

Using the steps above:

T = (K x 0.375 x 5,000)/12

Where:

D = 0.375 (3/8-inch)

F = 5,000 pounds

Only K remains an unknown. Table 1 shows the values available. Keep in mind that K values are all best approximations. For a lubricated, un-plated steel fastener, K = 0.17.

Therefore:

T = (0.17 x 0.375 x 5000) / 12 = 27 foot pounds

|

| Table 1. Nut factors for molybdenum disulfide lubricant |

Other Considerations

Using the methods described so far, end users will know how much torque to apply, but they have more to consider. As they tighten the fasteners, each fastener’s load affects the others as each is tightened. To help ensure uniform loading on all the fasteners, they must be brought up evenly by tightening in stages and in a staggered manner.

Historically, the star pattern has been used for the tightening sequence. ASME PCC-1-2010 describes this procedure in detail as the Legacy Tightening Sequence/Pattern.

As a brief overview, take each fastener to 25 percent, 50 percent, 75 percent and finally 100 percent of the required torque. In the example using the lubricated, un-plated fastener, the end users would take each fastener to 7 (6.75 calculated), 14 (13.7 calculated), 20 (20.25 calculated) and finally, to 27 foot pounds.

Conclusions

Proper fastener loading depends on friction control. For torque to provide predictable and repeatable loading, friction must also be predictable and repeatable. Fastener lubrication is one of the most effective ways to accomplish this. Keep in mind that other factors can affect friction—such as corrosion and re-used components. The best practice for critical applications is to use only new, clean and lubricated fasteners and to calculate the torque using the information and formulas described in this article and described in more detail in ASME Standard PCC-1-2010. P&S

Next Month:

What should I do about flange face damage: accept, repair or replace?

We invite your suggestions for article topics as well as questions on sealing issues so we can better respond to the needs of the industry. Please direct your suggestions and questions to sealingsensequestions@fluidsealing.com.