Two types of technology function best in challenging sealing environments.

Bearings

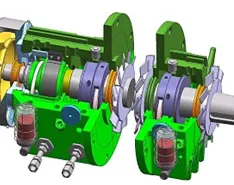

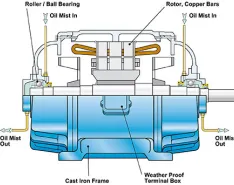

Bearings are small parts of pump systems that play a critical role. They bear the load of the pump, allowing rotation. They must be properly lubricated and temperatures monitored to prevent failure. These articles explain the causes of bearing failure and how to prevent them - thus protecting overall system life.

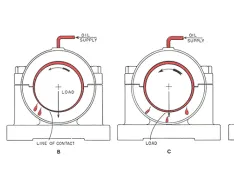

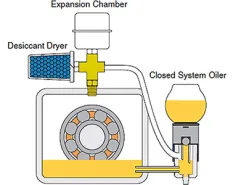

Understanding lubrication delivery methods and their applications.

Design, oil viscosity, clearance and functionality are important for proper function.

Proper procedures now can prevent problems later.

Learn advantages and disadvantages of this type of bearing and where they are best used.

Analysts can focus on bigger issues and spend less time on day-to-day maintenance.

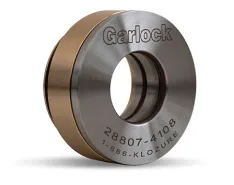

The importance of seal selection in harsh applications.

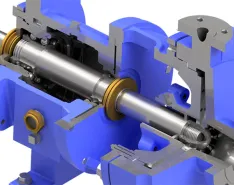

See what happens when bearings are overloaded.

Learn how a bearing isolator can prevent oil and grease issues, reduce lubricant use, decrease bearing failure and save money.

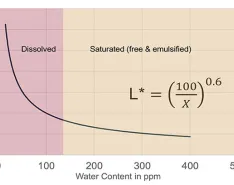

Maintaining a low level of moisture and humidity in pump bearing housings is critical.

Noncontact seals can help provide maintenance and protect bearing life.

This technology is for more than just troubleshooting.

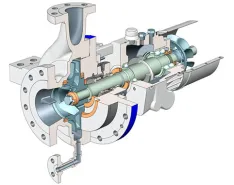

Upgrades improve pump reliability and reduce maintenance costs for operators.

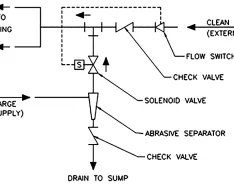

Solenoid valve problems needed identification and fixing.

The pros and cons of natural materials lignum vitae and rubber.

By the time water becomes visible in oil, damage is already occurring.

Recent developments should aid end users with decision to use oil mist.

When properly specified, bearing housing lubrication quality-enhancing components can be effective in preventing contamination.

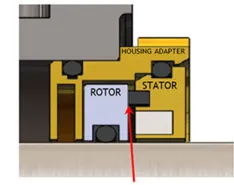

Magnetic drive pumps can suffer damage if not properly lubricated.

Learn which heating method is best for your equipment.

Consider additional options outside of the bearing housing to improve reliability and reduce operating costs.