A case for water utilities to adopt modern practices and technology.

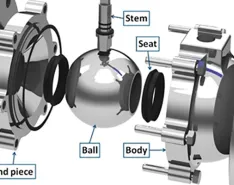

Valves

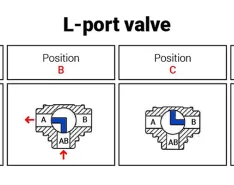

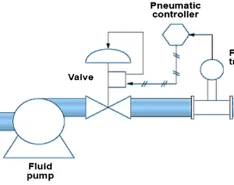

Valves regulate and control flow and pressure in pumping systems. They also play an important role in site safety. Understanding the types of valves and how they work can help end users select the right valves for their application’s use.

The flexibility of this equipment offers potential sustainability and efficiency benefits.

A glimpse at the common standards that affect potable water.

The use of carbon graphite enables reliable performance in harsh environments.

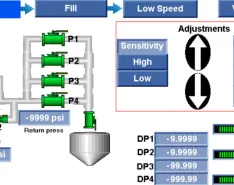

An in-depth look at the interactions that take place between a SCADA system and PLC.

The importance of valve packing loading precision.

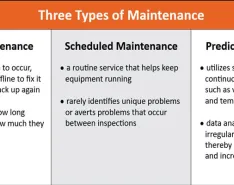

Avoid costly downtime with predictive maintenance.

An in-depth look at the potential benefits of pinch valves.

It is imperative to choose the right materials when working in caustic environments.

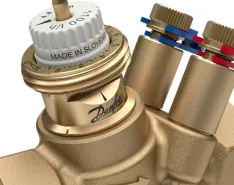

How implementing PICVs can simplify HVAC system design.

Social media has revolutionized the way valves are presented and sold.

Energy recovery systems produce energy from the flow of water in pressurized water pipelines.

The pros and cons of pneumatic, electric and hydraulic actuators.

Their ease of inline maintenance, reliable tight shut-off and fugitive emissions compliance can benefit most operations.

Identify what types of automation are possible and what level of control and accuracy is needed.

This material is a key component in oil and gas applications.

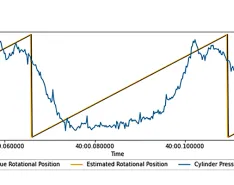

Physics-based and data-driven algorithms make earlier detection of faults possible.

Water hammer analysis software can help improve reliability of systems.

How the correct ball valve can provide flexible flow control.

Steady water pressure is important to daily functioning.

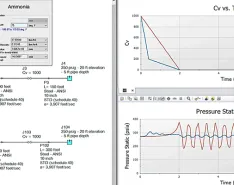

Understand flow control characteristics for valves in your application.

How actuators play a role in stages of flow control.