In scientific history, there are pivotal moments that stand as milestones, forever altering our understanding of the physical world. Among these moments, one of the most intriguing and historically significant experiments was conducted by Otto von Guericke on May 8, 1654, in the town of Magdeburg. This experiment, known as the Magdeburg Hemispheres Experiment, not only captivated the minds of the time but also provides a fascinating insight into the early use of gaskets in the scientific pursuit of understanding vacuum, air pressure and the power of innovative experimentation.

To appreciate the significance of the Magdeburg Hemispheres Experiment, a brief history of the man behind the groundbreaking trial, Otto von Guericke, must first be given. Guericke’s life was a wide range of diverse experiences. Born in the early 17th century, he was not just a scientist but also a man who had seen the world through the lens of a crusader. After his journeys, he eventually settled in the town of Magdeburg, where he would later assume the position of mayor.

During the 17th century, the scientific landscape was debating many questions and curiosities. One of the most interesting issues of the day centered around the existence of a vacuum. It was the great philosopher Aristotle who had posited that “nature abhors a vacuum,” suggesting that empty spaces were an impossibility.

Otto von Guericke, an inquisitive mind, sought to address this very question through experimentation. In 1650, he devised a remarkable apparatus, the precursor to the modern air pump. This ingenious contraption featured a piston and a cylinder fitted with one-way flap valves. Unlike a bicycle pump, which forces air into a tire, Guericke’s invention had the opposite purpose—it drew air out of a container. It was this invention that laid the foundation for his groundbreaking experiment.

Guericke’s experiment began with a straightforward yet profound idea. He used his new air pump to withdraw air from an iron vessel. The results were astonishing. Guericke demonstrated that the vessel now contained a vacuum—an empty space devoid of air. To illustrate this, he placed a ringing bell inside the vessel, and the sound became inaudible, as sound requires a medium, such as air, to travel through.

In subsequent trials, Guericke went even further. He revealed that a candle could not burn in a vacuum, as fire relies on the presence of oxygen in the air. In a particularly poignant demonstration,

he placed a dog inside the vessel, showing that a living being could not survive in a vacuum.

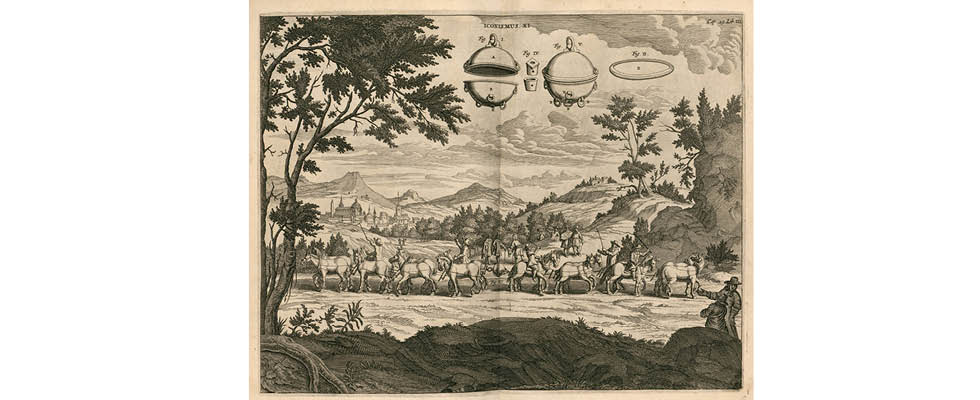

However, Guericke’s most famous performance took place on May 8, 1654, before Emperor Ferdinand III, drawing a large audience from all over Saxony. This experiment revolved around two large hollow copper hemispheres, which had been meticulously cast to fit together with a leather gasket in between. These remarkable objects would become known as the Magdeburg Hemispheres and were a pioneering example of gasketed joints held together by a vacuum.

The audience watched as Guericke carefully greased the rims of the two hemispheres and placed a gasket between them. With great precision, he joined them together, sealing them tightly. The climax of the experiment involved a blacksmith vigorously operating the air pump to withdraw air from inside the sealed copper globe.

As time passed, the task became increasingly more difficult. Guericke’s assistants joined in as the effort to pump air out intensified. The audience watched in awe as a team of eight horses was harnessed together, each connected to one hemisphere of the copper globe. Another team of eight horses was similarly connected to the other hemisphere. With a signal from Guericke, the two teams of horses strained in opposite directions, attempting to pull the two hemispheres apart. The crowd fell into an eerie silence as the powerful horses struggled, but no amount of whipping could succeed in separating the hemispheres.

Guericke addressed the emperor and the crowd, emphasizing that this was no mere trick. He explained that the only force holding the two hemispheres together was the air pressure surrounding them. The vacuum inside the globe created an absence of opposing pressure, resulting in a powerful external force that surpassed the combined strength of 16 horses.

The audience, including the emperor and his subjects, stood in amazement, and applause erupted. Guericke, however,

silenced the crowd, indicating the experiment had not yet concluded. The horses were untethered and led away. Guericke turned his attention to the air pump, and the crowd leaned forward in curiosity. Suddenly, a hissing sound filled the air as

the outside atmospheric pressure rushed into the hollow globe, filling the vacuum.

Then, without warning, the two copper hemispheres simply separated of their own accord. With the vacuum gone, the internal pressure equaled the external pressure, and there was nothing left to hold them together.

Guericke’s experiment became the stuff of legend, and he soon found himself demonstrating it all across Germany. The Magdeburg Hemispheres Experiment not only provided groundbreaking insights into the nature of vacuum but also left an indelible mark on the history of gaskets, scientific experimentation and our understanding of the physical world.

In essence, this historical account reminds us that at the heart of scientific progress lies innovation, experimentation and the quest to unravel the mysteries of the universe. Guericke’s pioneering work serves as a testament to the power of curiosity, the ingenuity of invention and the boundless potential of the human mind. The Magdeburg Hemispheres Experiment, a true hallmark of scientific discovery, will forever be celebrated as a defining moment in our collective pursuit of knowledge.

In the intricate world of power generation, there exists a realm where sealing a vacuum is not just important, but critically so. Imagine the heart of a fossil power plant, where the steam that powers our lives transforms back into water as the cycle concludes. At this juncture, a vacuum is created, a silent yet crucial player in the energy landscape.

Here is the challenge: within this vacuum, a network of valves and flanges awaits. To the untrained eye, they may seem impermeable, their surfaces untouched by the leaks that typically plague pressurized systems. However, appearances can be deceiving. In the absence of pressure, these components do not leak; they inhale. They suck in air from their surroundings, unwittingly introducing a critical issue known as dissolved oxygen (DO) into the equation.

The presence of DO is far from ideal. Chemists who keep a vigilant watch over power plants devote substantial effort to monitoring and combating it. DO can give rise to hot spots within the system, potentially leading to pitting and, in the worst-case scenario, causing damage to the boiler’s tubes. Power plants can ill afford such complications, given the critical role they play in supplying our energy needs.

To tackle this challenge, technology comes to the forefront. One such innovation making its mark is ultrasonics. Here is how it works: a skilled technician wields a highly sensitive microphone, attuned to frequencies our ears cannot discern. In the hushed confines of the power plant, this technician can listen for the unmistakable sound of air being drawn into the valves and flanges. This auditory insight provides a key advantage, enabling the detection of vacuum-induced leaks.

Armed with this knowledge, power plant teams can strategize and plan for the next scheduled outage. During this downtime, they can address the problematic valves and flanges, taking action to mitigate the intrusion of air. By doing so, they significantly reduce the DO levels in the feedwater, thus safeguarding the boiler and the entire power generation process.

While the technology aids in identifying leaks, the art of sealing these flanges primarily revolves around an often-overlooked hero: bolting. The intricate factors of pressure, temperature and fluid dynamics become secondary concerns in this context. Instead, the spotlight turns to the craft of bolting, a practice requiring precision and expertise. The key lies in executing a well-thought-out bolting pattern with the right amount of torque, ensuring that each bolt contributes to the system’s structural integrity.

This may seem like a modest task, but it is an essential one. The success of power plants hinges on these simple yet critical details. As power generation technology evolves, from fossil fuels to sustainable alternatives, the sealing of vacuums and precision bolting remain ever-relevant aspects of the process. They serve as a testament to the power of meticulous engineering, safeguarding our energy production and, by extension, our daily lives. The Fluid Sealing Association Gasket Manual can be found at our website and our knowledge base. The manual includes a detailed section on correct bolting techniques to ensure proper loading on flanged joints, including under vacuum.

We invite your suggestions for article topics as well as questions on sealing issues so we can better respond to the needs of the industry. Please direct your suggestions and questions to sealingsensequestions@fluidsealing.com.