In the cover article for the September 2013 issue of Pumps & Systems, “A Big Picture Evaluation Can Produce Big Savings,” the author advocated a systems approach to pumping system efficiency improvements. The author noted that the most common source of wasted energy in these systems are pumps that are not properly sized for their current applications, resulting in excessive throttling of the pump flow and operation of the pump outside its best efficiency point (BEP). This type operation can produce high levels of vibration that culminate in damage and the abbreviated functional lives of the bearings and mechanical seals. In these applications, the mechanical seals can serve as a harbinger of other maintenance issues resulting from the off-design operation of the pump equipment.

What Initiates Seal Failure?

Average mechanical seal life has increased significantly during the last 20 years, with improvements in mean time between failure of 50 percent during the last 10 years alone. However, seal service life can fall short of expectations if the seal is exposed to conditions outside its intended operating environment. In most cases, these conditions result from the pump being operated outside its designed application range.

A key takeaway from the September cover article is that a properly designed, selected and installed mechanical seal can fall well short of its optimal service life if the overall system is not selected and operated properly. In taking a systems approach to evaluate and optimize the operation of an existing pumping system, it is important to look beyond the failure modes that can result from improper system design and operation and drill down to the root causes of the failure.

Root Causes

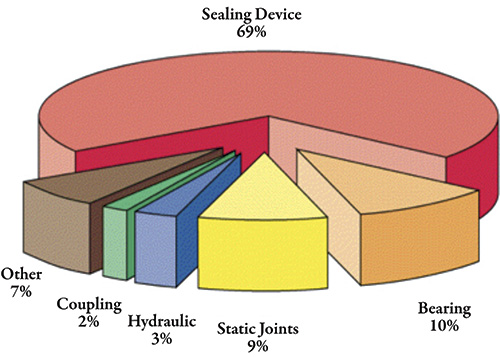

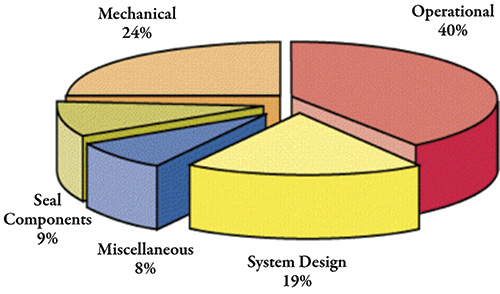

In the case of premature mechanical seal failures, several common root causes should be investigated and mitigated to ensure optimal performance of the overall system. Analysis of pump failures in process plants identifies a common set of failure modes with sealing devices being the most prevalent pump component for which failures are first observed. A compilation of investigations by several leading mechanical seal manufacturers points to off-design operation of the rotating equipment as being the leading contributor to these sealing device failures. The most common conditions from off-design pump operation that can be root causes of reduced service life are excess vibration transmitted through the pump interfaces and into the seal components and insufficient lubrication between the seal faces.

The components that result in pump failures and the type of failures are shown in Figures 1 and 2.

Figure 1. Pump component failures

Figure 1. Pump component failures Figure 2. Causes of pump failures

Figure 2. Causes of pump failuresVibration

Pump system vibrations come from several sources. Operation of a pump away from its BEP on the pump curve can cause recirculation and cavitation, which can be the source of vibration transmitted through the impeller and the pump shaft to the mechanical seal. When variable frequency drives are used, allowing operation over a range of speeds, the pump should not be operated near its critical speeds to avoid natural resonance of the pump system or components.

Pump system wear and degradation during use can also result in unacceptable vibration levels. Asymmetric wear of the rotating components, such as impellers, often caused by cavitation induced by off-design operation can lead to imbalances. This imbalance and resulting eccentric rotation can wear the contact surfaces in bearings and wear rings resulting in increased radial clearances that allow shaft “whip” to create vibration that is transmitted to the seal area. Another common cause of vibration in a pump system is the misalignment of the coupling or suction and discharge piping.

Regardless of the source, vibration can be transmitted to the seal in several ways and can manifest in failure modes. Some of the most common failure modes are:

- Fretting of the dynamic O-ring surface, resulting in the loss of axial tracking of the flexibly mounted seal ring

- Breakdown of the lubricating film stiffness between the seal faces that result in face wear and chipping

- Fatigue failure of the welds in a metal bellows seal

- Wear of drive mechanisms—including the pins, lugs—and the mating slots, grooves or holes resulting in the loss of axial tracking and damage to the seal rings

- Loosening of the drive collar set screws, causing a loss of torque transmission to the rotating components

Seal Face Lubrication

The preservation of face lubrication is a critical requirement for a mechanical seal system in a pump. Wet contacting mechanical seals rely on the existence of a fluid film between the seal faces to minimize wear and friction and provide reliable performance. To achieve this objective, mechanical seal support systems are selected to provide a suitable environment in the seal chamber for the seal to operate at its optimum performance by preserving the fluid film properties between the seal faces.

Pump operation away from its BEP can result in conditions that cause the degradation or loss of the fluid film. This leads to face contact that results in high friction, locally increased temperature and accelerated wear. The seal experiences rapid face degradation and eventual failure. Some common conditions that contribute to degradation or loss of the fluid film are:

- Excessive vibration transmitted to the seal chamber caused by cavitation, internal recirculation or asymmetrical wear

- Cavitation (vaporization) of the fluid in the seal chamber (and, therefore, vaporization of the fluid film)

- Temperature increase in the seal chamber under low-flow conditions causing vaporization of fluid in the seal chamber

- Insufficient cooling flow from the mechanical seal support system (such as process flush or barrier fluid circulation)

Critical Seal Components

Within the seal design, the components that are most sensitive to vibration and insufficient lubrication are typically the mating pair of seal rings. The seal ring materials are selected based on the defined conditions of the environment being sealed. Those conditions include factors—such as temperature, the media being contained, system pressures and interface surface speeds.

The seal components’ interface conditions can change quickly and dramatically with exposure to vibration, insufficient seal face lubrication or other upset circumstances. While the sealing system design incorporates features to regulate the interface conditions, the seal faces can become damaged when off-design pump operation forces them into settings for which they were not designed. Slight damage can result in a leakage at the sealing interface that is caused by systemic issues unrelated to the materials or the seal design.

Conclusions

Seal performance degradation is often caused by improperly operated pumping equipment. Energy and maintenance costs and unplanned downtime may be saved if a proactive systems approach is taken to pump system efficiency and investment is made in process modifications and system upgrades to mitigate the root causes of these failures. While properly selected mechanical seal designs help increase the seal’s tolerance, the most reliable approach is a pumping system with a strong focus on eliminating or minimizing these root causes of reduced mechanical seal service life.