Corrections can be a sustainable, cost-saving measure and should be considered by companies with a large installation of these types of motors.

04/14/2016

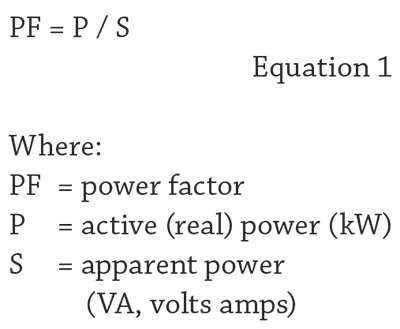

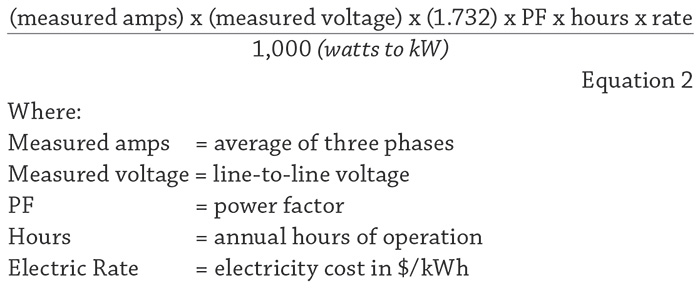

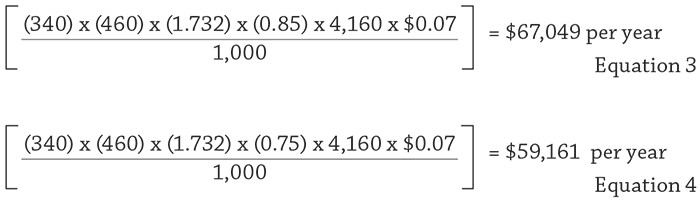

What is power factor, and how does it impact your bottom line? Anyone with large induction motors in their plants or those who have been the recipients of power factor correction charges from their electric power utilities should read this article carefully. The Institute of Electrical and Electronics Engineers and the International Electrotechnical Commission define power factor as the ratio between the applied active (real) power and the apparent power (see Equation 1).

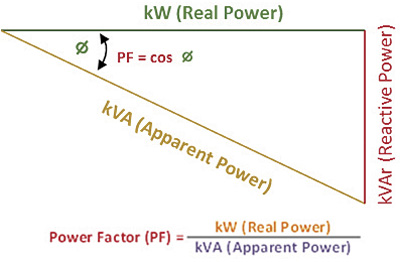

Figure 1. The graphic shows how the power factor is derived. The kW, or real power, is what a user receives. The kVAr, or reactive power, is the extra power transmitted to compensate for a power factor less than 1.0. The combination of the two is called apparent power (kVA or volt-amperes). (Graphics courtesy of WEG Electric)

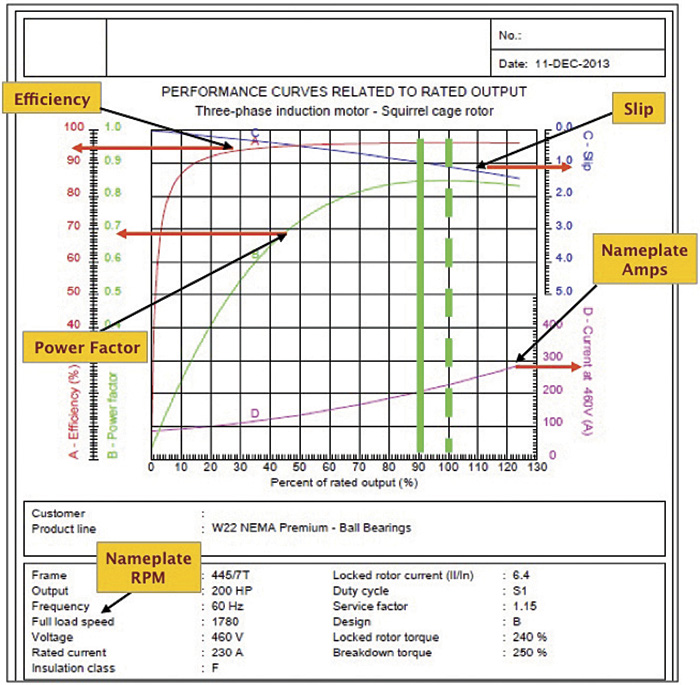

Figure 1. The graphic shows how the power factor is derived. The kW, or real power, is what a user receives. The kVAr, or reactive power, is the extra power transmitted to compensate for a power factor less than 1.0. The combination of the two is called apparent power (kVA or volt-amperes). (Graphics courtesy of WEG Electric)  Figure 2. At reduced load, power factor drops off much quicker than efficiency.

Figure 2. At reduced load, power factor drops off much quicker than efficiency.- The electrical load on the utility is reduced, allowing the utility to supply surplus power to other consumers without increasing generation capacity.

- Most utilities impose low power factor penalties, which can be substantial. By correcting the power factor, this penalty can be avoided.

- High power factor reduces the load currents, so considerable savings are made in the cost of hardware.

To read more Motors & Drives articles, go here.