How this equipment seals and what features to consider when making a selection.

Mechanical Seals

An introduction to mechanical seals and their applications.

Webinar

This webinar will look at the data behind seal failure causes, help to explain what is really happening and what pump users can do to extend the life of their pumps and systems.

Sponsored by

Failure analysis can help define what a seal experienced during operation before failing.

In this report, the Fluid Sealing Association explains that not all chemicals in this category are dangerous, namely polytetrafluoroethylene.

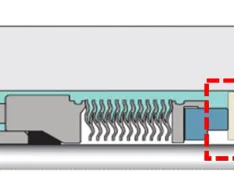

Learn about the basics of dry gas seals and where they can be used in various applications.

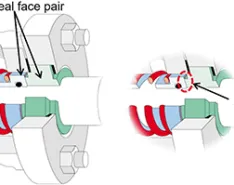

Hydropad technology lowers face operating temperatures and improves efficiency.

In Bloch's latest column, he discusses how to navigate outdated standards.

With multiple options, selecting the most effective technology is the first step in increasing rotating equipment reliability.

Adam Slade of John Crane joins the podcast to give the lowdown on NSF 61.

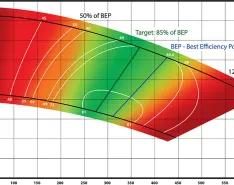

Pump selection involves a series of tradeoffs.

Diamond seal technology can add value components in critical field applications.

There are important factors and regulations to consider when choosing to repair rather than replace a mechanical seal

White Paper

Understanding when to use—or not use—mechanical seals is important for protecting the entire pumping system.

Sponsored by

Optimize material and surface treatment selection.

Necessary precautions can lead to more success with the seal and systems.

How to calculate if the bolt material can handle gasket stress.

What are the best practices for sealing equipment with high thermal expansion?

A liquid-lubricated seal may have no visible leakage.

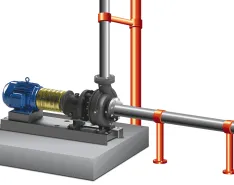

There has been an effort to upgrade pumps originally designed for packing to accommodate mechanical seals.