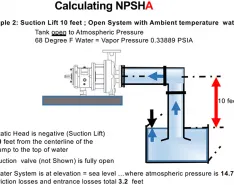

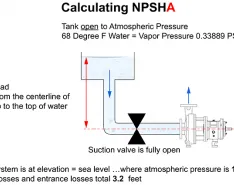

Inspired by recent events, I hope to clear up the continual confusion around net positive suction head (NPSH), specifically as it pertains to self-priming pumps on a lift application.

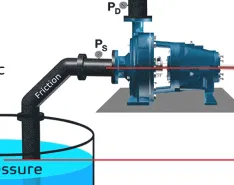

NPSHA

If a higher speed pump is desired, then more attention will need to be paid to the pump’s suction performance.

Hydraulic Institute answers this challenging question for a pump system.

Deciding between placing this equipment on the suction or discharge side of the pump.

How this practice can affect pump efficiency, NPSHr, axial vibration and more.

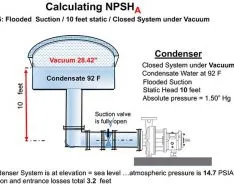

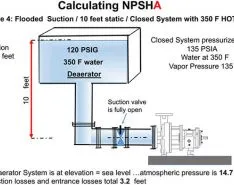

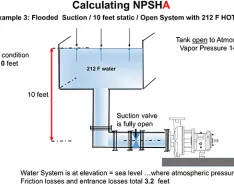

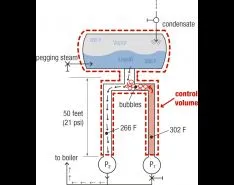

The equivalent suction lift is equal to the difference between the “vacuum effect” and the net submergence.

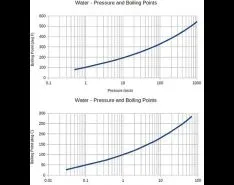

Don't forget to take vapor pressure into consideration.

Learn the difference between suction lift and flooded suction.

The first of a five-part NPSH primer series.

Because cavitation is unavoidable in pump operations, understanding how to reduce it using NPSH calculations is necessary to maintain pump functionality and health.

Understanding this complex topic can help end users avoid common pitfalls.

Pump sensors can improve system operation and detect dangerous faults.

Higher temperatures reduce water’s lubricating effect and stress seal faces.