The Northeast Transmission Line project’s impact on Houston’s water supply and subsidence mitigation.

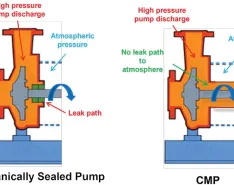

Pumps

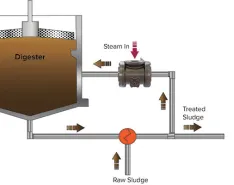

Innovation and progress in wastewater treatment.

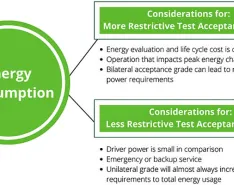

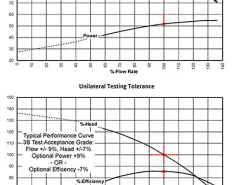

Proper selection of a pump performance acceptance grade is critical to ensuring a pump’s functionality.

Exploring practical applications for aftermarket materials.

How these pumps compare to traditional pumps.

The role of protective covers in preserving critical infrastructure.

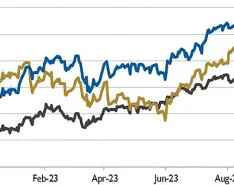

Factory production, construction spending & U.S. petroleum product exports rise.

This mix of CIP can optimize energy, chemical, water and product consumption.

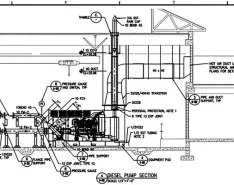

Considerations for constructing an emergency bypass pumping system.

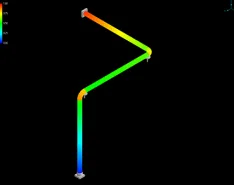

Simulation software can be a beneficial tool when used in incorporating rubber joints.

Specifying the appropriate factory pump performance test standard.

Five things that indicate it’s time to look at your air compressor system.

Advocate and educator Fredi Lajvardi discusses the keys to unlocking the potential of future employees.

How a food processing facility reduced fats, oils and greases in its aeration basin.

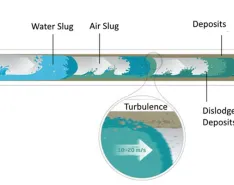

How to avoid cavitation from the outset.

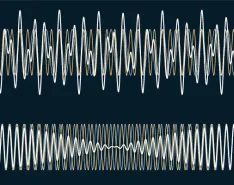

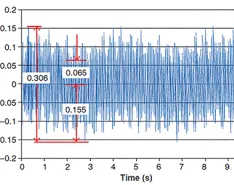

Understanding the fundamentals of pump vibration.

Palgrave has presented throughout the U.S., Middle East and Europe on centrifugal pump technology and has authored a book.

A guide for new engineers and a refresher for experienced engineers.

Gagnon founded Industrial Fluid Consultants, Inc. (IFC), in 1994.