In March 1980, I attended the ASME symposium on Predicting the Performance of Centrifugal Pumps and Compressors in New Orleans. I was about three rows from the podium, sitting next to a fellow who introduced himself as “Hal Anderson” from Scotland.

He said that he had one foot on his motorbike and the other in the grave. It turned out that he was H. H. Anderson of area-ratio fame and was at the symposium to deliver a paper on his area-ratio principle.

As we walked to the cafeteria and ate lunch together, Anderson was approached by people requesting his autograph (one was from Australia). He was well-known and well-respected—and his area-ratio principle was well-founded.

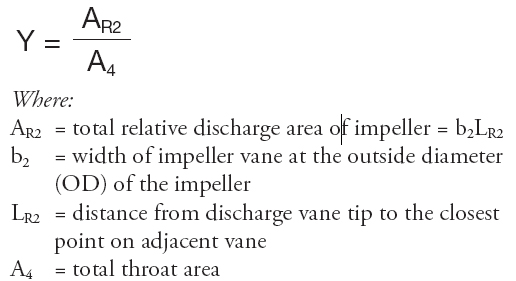

Anderson introduced the area-ratio principle in 1938 [1]. The definition is:

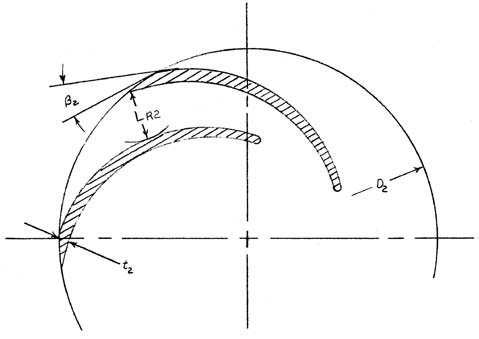

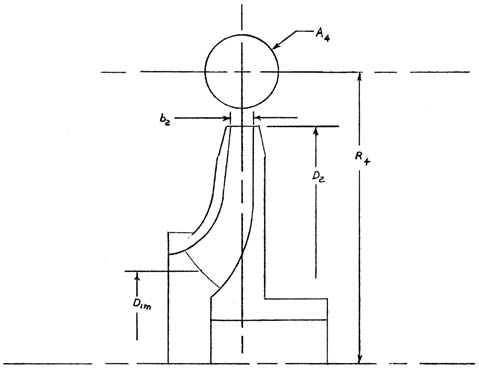

Figures 1 and 2 illustrate the two areas.

Figure 1. Partial impeller plan view showing pertinent performance parameters

Figure 2. Partial impeller profile view showing pertinent performance parameters

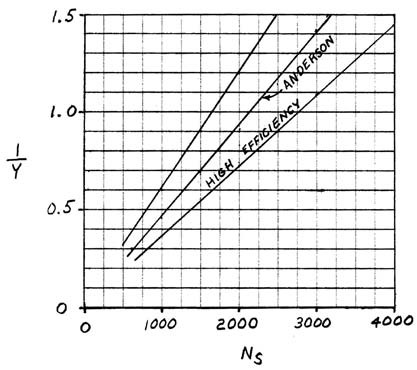

Anderson's work (1, 2, 4, 5) showed a definite correlation between Y and NS (specific speed). The higher values of Y correlated to lower values of specific speed. Both Thorne [3] and Jekat [6] also wrote about the area ratio principle. What seems to be the most useful is contained in reference 6.

Figure 3. Jekat's chart plotting 1/Y, the inverse of the area ratio, as a function of Ns

Figure 3 is a redrawn graph from Jekat [6], with straight lines substituted for slightly curved lines. The text says that the “band results from the author's data and shows the considerable range of area ratios which are used in actual pump designs.” (Jekat recommended against extrapolating the graph to lower values of NS.) It is possible to write equations for the (straightened) lines on the graph. Jekat's “high efficiency” line can be expressed as:

I have obtained high-efficiency pumps with numerators ranging from 2,450 to 2,750. Note that a Y value of 1.0 occurs where NS is about 2,500, right in the middle of the Worthington graph, right where maximum pump efficiencies reach their peak. Is that just a coincidence? (To view the graph, see “Centrifugal Pump Specific Speed” in Pumps & Systems, September 2011.)

Three years after that visit in New Orleans, I wrote to Mr. Anderson with a question about throat area. My letter was returned, unopened, containing a hand-written note “gone away.” Had he taken his second foot from his motorbike and placed it also into the grave? I never heard.

Pumps & Systems, November 2011

References

- Anderson, H. H., The Harland Engineering Company, Scotland, “The Hydraulic Design of Centrifugal Pumps and Water Turbines,” ASME paper 61-WA-320, American Society of Mechanical Engineers, New York, N.Y., 1961.

- Anderson, H. H., “The area ratio system,” World Pumps magazine, June 1984.

- Thorne, E. W., Worthington-Simpson Ltd. U.K., “Design by the Area Ratio Method”, Pumps 1979, Sixth Technical Conference of the British Pump Manufacturers' Association, Canterbury, England, 28 – 30 March, 1979.

- Anderson, H. H., “Prediction of Head, Quantity and Efficiency in Pumps – the Area Ratio Principle,” The 22nd Annual Fluids Engineering Conference, The American Society of Mechanical Engineers, New Orleans, La., March 9 – 13, 1980.

- Anderson, H. H., Weir Group, Centrifugal Pumps, Third Edition, Trade & Technical Press LTD., England, 1980.

- Jekat, Walter K., “Centrifugal Pump Theory,” Section 2.1 of the first edition of the Pump Handbook, edited by Karassik, Krutzsch, and Fraser, McGraw-Hill Book Co., New York, N.Y., 1976.