For the non-expert in pump technology, selecting the most appropriate pump technology for a specific application or process system can be challenging because many of today's pumps are so versatile that they are suitable for a considerable range of applications. Rotary positive displacement pumps, peristaltic pumps and reciprocating positive displacement pumps all cross application boundaries where there is a requirement to introduce a specific volume of liquid into a process system. Selecting which of these is the best option requires careful consideration and should always involve the expertise of the pump manufacturer.

Where an application has a requirement for the in-line proportioning and dosing of liquids, the reciprocating positive displacement process pumphas historically dominated the market and continues to do so. The issues affecting the choice of a metering or dosing pump as opposed to other types of pumps are normally associated with precision over a range of flows and the fact that the capacity is not influenced by pressure fluctuations within the process, which is the case with rotary pumps. It can handle a wide range of fluid types at varying temperatures, can operate at high pressures in excess of 1,000bar if required and provide high levels of accuracy and repeatability.

The breadth of applications for these pumps is considerable, with market sectors ranging from toiletries and detergents, to pharmaceuticals, water and waste treatment, food and beverages, power generation, chemical processing, petrochemicals and oil and gas recovery. The metering pump is equally at ease with dosing fragrances and colours in toiletries as it is with pumping hydrocarbon condensate offshore and liquid CO2 in cryogenic duties.

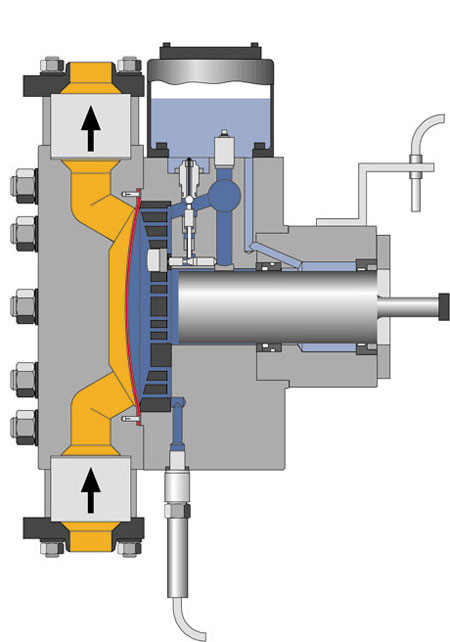

Cross section of a hydraulically actuated diaphragm pump head

Selecting the Correct Pump

The most common issues facing users are improved safety, greater efficiency and lower running costs. The first two issues have been addressed by the development of diaphragm pump heads, which prevent product leakage and contribute to higher levels of safety and more economic use of ingredients. Users are also conscious of the overall life -cycle costs, which consider known factors such as the initial investment and subsequent spares, maintenance, downtime, power consumption and efficient use of the product being handled.

The application usually determines the pump to be used so it is important to clearly understand the fluid's characteristics,like viscosity, solids content, abrasiveness, corrosiveness, toxicity and hygiene. It is also necessary to consider other parameters including, delivery volume and pressure, temperature, flow characteristics and vapour pressure. The correct material for the pump head must be selected according to the fluid's characteristics. For toxic materials or exacting applications where security and safety are priorities, a diaphragm pump head is usually the first choice. For less demanding applications, a plunger pump head will normally suffice.

Since metering pumps are typically employed as part of an integrated processing system, several factors influence what typeis appropriate. These could include NPSH (Net Positive Suction Head) calculations, a review of inlet and discharge pipe diameters and lengths and whether any constraints exist within the system. The environment also plays a part in the selection of the pump materials. Metering pumps are used in some of the most arduous environments and conditions, ranging from offshore oil and gas platforms where sub-zero temperatures are frequent, in remote deserts where temperatures are high and the ingress of sand is a distinct possibility or in tropical areas where the presence of moisture has to be eliminated. Every type of working environment will influence the material is used for the pump components.

Only when a complete profile of the medium to be pumped and the processes involved are fully documented, can the type and design of metering pump be specified. In compiling this profile, it is always sensible to review any previous pumping experience with the fluid being handled.

Multiple pump head arrangement for metering several ingredients

Metering Pump Types

The metering pump is highly versatile and ideal for the continuous, in-phase metering of single or multiple liquid systems at varying rates. Significantly, it is the only pump with two flow adjustment methods-speed and stroke length-that can be used independently or simultaneously to provide optimum performance.

For instance, in a process where an ingredient has to be added accurately to a varying main flow, the proportion can be maintained by speed adjustment, while any corrections necessary to maintain product quality can be made by adjustment adjusting stroke length. The metering pump can be finely tuned to the process system's requirements. Manual, pneumatic or electric control options are available as are flameproof designs for pumps used in hazardous areas.

Metering/dosing pump technologies fall into three categories: piston/plunger, mechanical diaphragm and hydraulic diaphragm. The basic technology is well proven, and continuing developments through the introduction of new manufacturing processes and materials means that these pumps are keeping pace with the growing and varied requirements of all industry sectors.

The standard plunger pump head, consisting of a housing, displacement plunger, seal arrangement, pump valves and suction/discharge side connections, is commonly used where high pressures and high flow rates are encountered. The simple design and small number of components allow a low dead volume and high volumetric efficiency.

Mechanically coupled and hydraulically actuated diaphragm pump heads have been the focus of new developments in metering pump technology. These pump heads are normally specified where toxic materials are handled and leak-proof performance is required. As a result of the wider variety of materials that can be used for diaphragms, diaphragm pumpheads are now capable of accommodating hazardous, toxic and dangerous liquids at variable flow rates and pressures. With greater emphasis placed on safety and environmental considerations and as further legislation is introduced,users are increasingly moving towards diaphragm pumps and away from the traditional plunger design.

Hydraulically actuated double diaphragm pump heads now incorporate diaphragms made from either PTFE or stainless steel and are capable of handling pressures of up to a 1,000 bar and above. Users are advised to seek out pump head designs that incorporate a diaphragm failure indicator as this eak-free pump head design will continue to provide continuous service even in the event of one diaphragm failing.

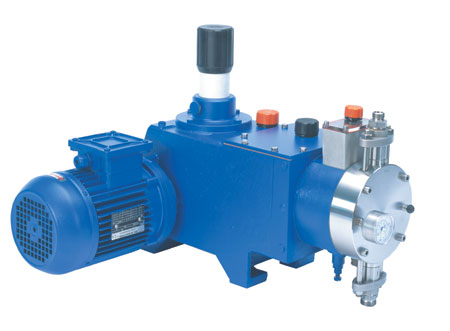

Hydraulically actuated diaphragm metering pump

Challenging Applications

The options for high pressure transfer of hazardous fluids have traditionally been limited to reciprocating fixed stroke piston type positive displacement, high speed, or multi-stage centrifugal pumps. All these have their limitations, with respect to sealing, wear and consequent potential for leakage.

The availability of a hydraulically actuated, double diaphragm pump capable of handling pressures up to 1,000 bar with leak-free operation, is changing this situation. Process diaphragm pumps can provide a smooth product flow across a wide operating range, including low speeds, and will accommodate the widest possible range of duties for all critical pressure processes. By employing low -maintenance reduction gears, energy consumption is reduced to the absolute minimum and almost silent operation is ensured.

Metering pumps are used for single point or multi-ingredient dosing throughout all areas of industry. Single point dosing typically involves the addition of a specific fluid accurately and in proportion on a continuous basis. Multiple liquid applications can be handled on a multi-head pump unit driven by a single motor, with the individual liquids metered independently to predetermined points in the process or brought together to create a blend. This application can involve a variety of fluids in any range of flows and proportions. Each of the fluid components is blended in correct proportions according to the recipe to obtain the desired mix.

Conclusion

The changing requirements in process engineering are encouraging pump manufacturers to examine current technologies with a view to developing new techniques and materials. At the same time, there is a push for more economical and efficient dosing and proportioning systems.

The market for dosing and proportioning is very diverse and the demands of each industry are different. However, drawing on the experience gained in one industry and applying it to another has proved to be highly effective in the system design process. Although the basic concept of a dosing and proportioning system is standard, the pump manufacturer knows how and where its components are customized for each application. The onus, therefore, lies with ensuring that all available data can be considered to facilitate well engineered selections and solutions.

Pumps & Systems, March 2010