With the inexorable rate of carbon emissions over the last two centuries, global warming has become an existential threat that demands action. The Paris Agreement set targets to stabilize the world temperature increase to below two degrees Celsius, but these aims require dramatic shifts in how energy is produced and sourced.

There is no cure-all solution to this problem, but hydrogen has the potential to be a key initiative on the path to net zero. Hydrogen is multifaceted and used in various industrial processes, from chemical and steel production to transportation. The emissions produced by gasoline and diesel are significant pollutants, while hydrogen only emits water and warm air.

The scaling up of hydrogen is increasingly becoming central for governments and industry energy policies. The security given by multiple energy sources also allows governments more freedom in case one source becomes unavailable for geopolitical or other reasons.

The Hydrogen Industry

Decarbonizing will allow companies to reduce their emissions and use low-carbon power sources to positively impact efficiency in industrial and domestic applications and global emission reduction. Using hydrogen and renewable energy is one of these approaches, alongside carbon capture and storage. All these efforts combine to have a substantive action on the necessary decarbonization of the world.

Currently, most hydrogen is produced by steam methane reforming (SMR). Without carbon capture and storage (CCS), it is the least environmentally desirable option, known as gray hydrogen. When carbon emissions from this process are captured and stored (often underground), the resulting hydrogen is known as

blue hydrogen and has a reduced environmental impact.

An alternative process utilizes electrolysis to produce hydrogen, where an electric current is passed through water to split it into oxygen and hydrogen. When the electricity is generated from renewable sources, it is called green hydrogen and, from nuclear power, pink hydrogen.

The production of green hydrogen is increasing rapidly, but not enough is currently being produced to satisfy demand. In the short term, the transition from gray to blue hydrogen can be considered technically and financially more accessible, as it can use existing infrastructure. In 2021, governments and businesses began working together to promote the use of hydrogen—preferably green.

Hydrogen is transported in compressed or liquid form using pipelines, rail or road. At its point of use, it can also be converted to ammonia and cracked (split back into hydrogen and nitrogen). The use of hydrogen to power long-haul transportation like trucks and tractor-trailers is likely to be a growth area.

One argument suggests that thinking in terms of overall carbon footprint—rather than in terms of colors of hydrogen production—is preferable. For example, blue hydrogen might be a bigger pull in the short term because of the existing infrastructure assets. Green hydrogen, conversely, is in the process of scaling up, and there is not yet enough green hydrogen to cover what is needed. Balancing different ways of producing hydrogen may be a better approach, and this balance is something the industry is still working out.

Challenges

Two main challenges are the issues of scaling up production of green hydrogen equipment and making the wider production and use of hydrogen cost-effective. The number of green hydrogen manufacturers is still relatively low, and scaling up must be done cost-effectively, both in terms of investment in production and the final product price. Government grants and subsidies can accelerate adoption, which may offset the higher cost of production of gray and blue hydrogen.

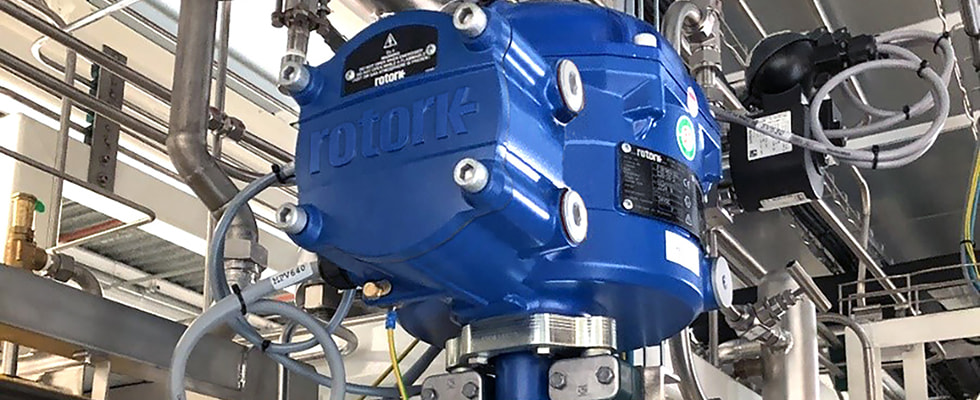

Hydrogen is an explosive and flammable substance, so explosion-proof products (with approvals such as ATmosphere EXplosible [ATEX], Canadian Standards Association and International Electrotechnical Commission for Explosive Atmospheres [IECEx]) must be used in its production, distribution, delivery and usage. As hydrogen is colorless, odorless and tasteless, leaks are hard to detect without accurate control and instrumentation.

Hydrogen transport is a challenge, with any risk of explosion or leakage affecting the public. Precise product flow and fail-safe operation are essential in converting hydrogen to and from its transport medium.

Importance of Flow Control

Correctly specified flow control equipment can provide a safe working environment, increase process efficiency (by moving quickly and precisely to a set position), reduce emissions, minimize maintenance, increase equipment lifetime and increase operators’ profitability. Hydrogen plants require emergency shutdown (ESD) procedures for control and safety needs.

Green hydrogen seems to hold the greatest potential as a clean fuel to support the desperately needed global energy transition. However, this sits more on a medium- to long-term timeline, and it is evident other mechanisms must be considered to speed up this transition for many reasons. This includes the potential for blue, pink and other possible methods of producing low-carbon hydrogen for industry and all other emerging sectors.

In each case, high-performing, critical flow control systems are required to provide safe operation, while allowing the equipment manufacturer to standardize, simplify and scale up their technology cost-effectively. This in turn will allow green and other low-carbon hydrogen to be produced cost-competitively in the market.