The use of ultraviolet (UV) mercury lamps in point-of-entry (POE) water treatment has provided homeowners with microbially safe water throughout their homes. However, as concerns loom around bans on mercury lamps, either from the Minamata Convention or consumer sentiments, more OEMs have been investigating UVC light-emitting diodes (LEDs) as a potential way to access the UV spectrum for their products.

In addition, the industry is adapting to regulations around forever chemicals, often categorized as per- and polyfluoroalkyl substances (PFAS), which focus on both production and abatement to reduce exposure to these materials. Treatment of incoming or feed water in residential, commercial and public buildings is meant to ensure both compliance with these regulations and safety of the water supply.

Traditional POE treatment methods include reverse osmosis (RO) and granular activated carbon (GAC). While thesemethods remove the trace PFAS chemicals present in the incoming water, they also remove some of the protective chemicals, like chlorine, that ensure the potability of the water throughout the home. Removing chlorine increases the risk for opportunistic property piping pathogens (OPPP) and biofilm growth.

This global regulatory environment around potential mercury bans and PFAS regulations is increasing the interest in applications that include UVC LEDs at the POE, particularly as their performance improves to meet the application needs.

Improvement in UVC LED Performance

In the point-of-use space, UVC LEDs have several advantages over traditional UV lamps. They make the system more

energy-efficient, have a longer life span and are less likely to break or malfunction. In addition, they can help to protect

people from waterborne illnesses while having no adverse effect on the temperature or odor and taste of the treated water. Their compact size enables more design flexibility and provides a

more optimal output for disinfection.

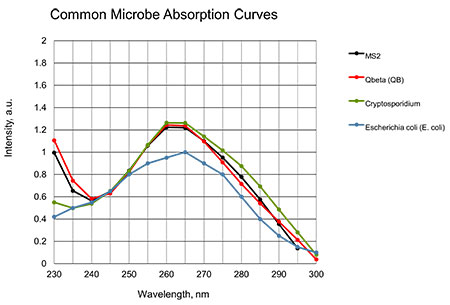

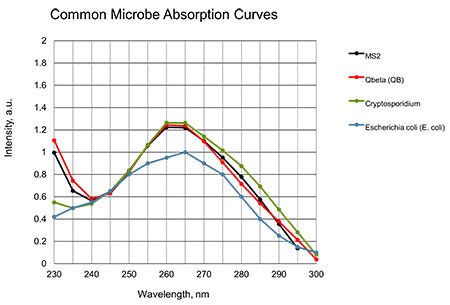

UVC LEDs offer a tremendous benefit in UV efficiency primarily due to the wavelength emission. In UV disinfection, short wavelength ultraviolet (UVC) light in the range of 250 to 280 nm disrupts the DNA of microorganisms, rendering them unable to reproduce. The action spectrum for bacteria is commonly reported and shown as a response from 200 to 300 nm with a peak between 265 to 267 nm wavelengths, with some variation across species (Image 1). Low-pressure mercury lamps emit a discrete wavelength at 254 nm whereas UVC LEDs can be tuned by the manufacturer to emit in a specific wavelength range.

When calculating system needs, it is important to understand the target microbe, or biodosimer, that is being used to design the system and its spectral response. A biodosimer is a surrogate microbe used to measure the performance of a system to ensure it delivers the disinfection efficacy required for the application. These are often defined by industry standards, such as the National Sanitation Foundation (NSF), or regional regulatory standards like the

Environmental Protection Agency (EPA). However, some manufacturers may prefer to use a specific microbe based on their own application requirements.

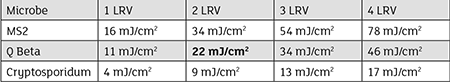

Once the target microbe is selected, one can consider the dosage—or energy required to reach a specific log reduction of a target microbe. For example, with NSF 55 Class B, the disinfection target is 2.0 log reduction value (LRV) at the beginning of product life for the surrogate Q-Beta—which according to Table 1, requires a dose 22 millijoule (mJ)/centimeter (cm)2 within the system.

Status of POE Systems

Generally, POE UV treatment systems can vary greatly in flow rate from 5 to 30 gallons per minute (gpm). The disinfection dosage performance can also vary from 16 mJ/cm2 to 40 mJ/cm2 with the dosage requirement often increasing as the flow rate decreases. Typically, UV lamp systems will employ a 35-watt low pressure mercury lamp for 9 gpm flow rate. This provides 11.5 watts of UVC energy at 254 nm for a dosage of 30 mJ/cm2.

Source: scholar.colorado.edu/downloads/rn301175t

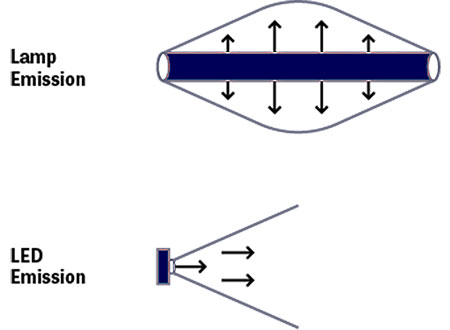

UVC LEDs are available in a range of peak wavelengths, with those in the 260 to 270 nm range providing a more consistent performance across multiple microbes (Image 1). While a lamp will emit the total energy across the entire length of the light source, LEDs provide more intense UVC energy that reactor designers can focus within the system (Image 2). They also emit as a point source, meaning the output intensity is focused and can be more easily directed within the system. This, coupled with the more optimal wavelength for disinfection, means that when moving from a mercury-based system to an LED-based system, less UVC energy is required for the same performance level. Understanding this, we can then consider an example POE system operating at 9 gpm and requiring a 3 log reduction of Q Beta. According to Table 1, the dosage required to achieve a 3 log reduction of Q Beta is 34 mj/cm2 at 254 nm. Thus, using the absorption curve, the required dosage at 265 nm to be 28 mj/cm2 can be calculated. A 35-watt mercury lamp will provide nearly the amount of UVC energy required to meet the disinfection requirement at 11.5 watts of UVC for a dosage of 30 mj/cm2. However, using an LED emitting in the peak germicidal wavelength from 260 nm to 270 nm, the system would require approximately 9.5 watts from the LEDs.

These calculations assume a basic design with moderately reflective surfaces within the reactors. Reactor design can be further optimized to balance the specifications of the existing technology with the disinfection performance and economic goals of the application.

Historically, there have been a few niche players that specialized in designing and building LED-based reactors. However,

as adoption has increased, there are now more mainstream companies that can provide varied sophistication in design to meet the performance and economic goals of a system. In the point-of-use space,

the performance of UVC LEDs is now at a point where the reactor designer can use less expensive materials and simpler designs to meet economic goals around the total system.

In larger flow cases like POE, the experience and expertise of designing systems with UVC LEDs in water reactors is paramount. Broadly, commercially available UVC LEDs meet the need for point-of-use markets, making reactor design easier to achieve. They also meet the entry conditions for applications in POE, and relying on companies that specialize in LED-based reactor design allows OEMs to leverage the full benefits of the UVC LED platform across their product lines. As the market need for UV disinfection in POE systems grows, it is anticipated that more OEMs will to turn to UVC LEDs as their platform technology as both the performance of discrete devices and overall system design improves.