Various pumping systems, whether equipped with packing seals or mechanical seals, rely on seal water flush for optimal functioning. Seal water flush plays a crucial role in cooling the seal and the shaft, providing lubrication and purging impurities from the seal. However, several factors can influence the volume of water a sealing system consumes, including product temperature, seal water temperature and pressure, rotation speed and the ambient system temperature. Without adequate controls, systems often use excessive amounts of seal water.

Different sealing solutions have specific flow and pressure requirements for seal water flush, and surpassing these requirements offers no tangible benefits. The processes of purging impurities and lubricating the seal usually demand only minimal amounts of seal water. Although cooling may necessitate more water, the quantity used often far exceeds the actual requirement. Seals lacking flow controls can easily consume 20 to 30 gallons of water flush per minute, a figure that can be reduced through easily implemented conservation practices.

The advantages of reducing seal water usage for end users include cost savings on water consumption and wastewater treatment, enhanced seal reliability, improved equipment uptime and compliance with increasingly stringent environmental regulations. To conserve water in their systems, end users should consider implementing the following strategies:

Control valves

Control valves function similarly to household water faucets, allowing operators to flush the system with seal water when cooling is needed. However, end users keep these valves wide open, leading to increased water consumption, wastewater production and the need for extensive seal water filtering capacity. To achieve water savings, end users should monitor and open these valves only when necessary.

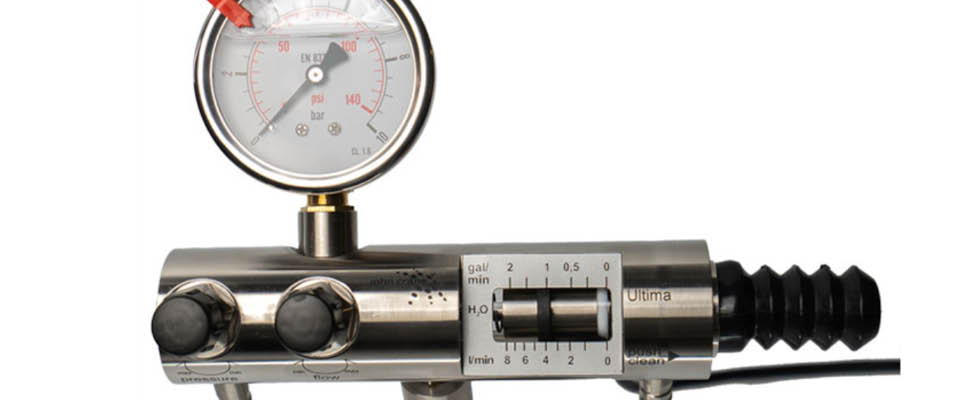

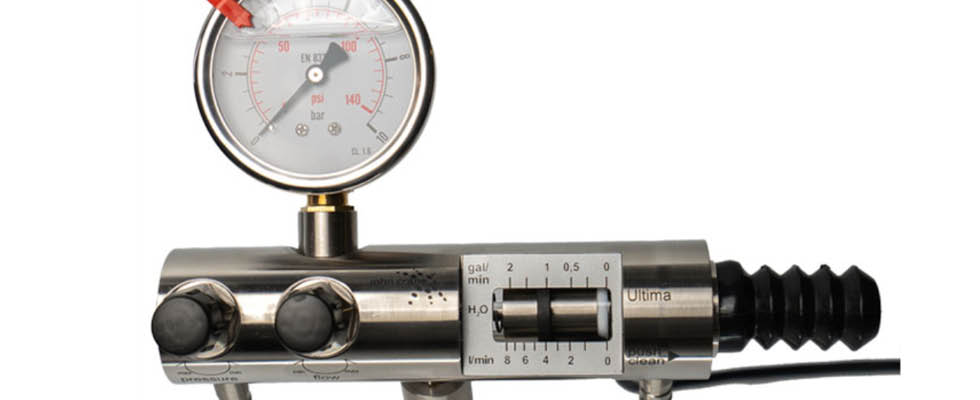

Flow meters

Flow meters, an advancement from mechanical control valves, can reduce seal water consumption while enhancing seal reliability. These devices use two valves to regulate seal water flow and pressure through a metering tube, ensuring that flush water meets the sealing solution’s requirements. Flow meters provide pressure and flow readings, allowing the end user to adjust the flush water as needed to maintain proper seal water pressure and flow for optimum sealing performance. The ability of flow meters to adjust the seal water flush pressure and flow can reduce seal water consumption by up to 90% compared to an unmetered flow controlled seal flush.

Smart water control systems

Smart water control systems represent the most sophisticated solution for seal water conservation. While flow meters offer substantial water savings, smart water control systems can reduce water consumption by up to 97% beyond the savings achieved by flow meters. These systems regulate water consumption based on seal temperature, allowing seal water to flow through the system as necessary to cool the seal.

Smart water control systems employ methods such as temperature-activated alloys with memory capabilities and spring-loaded devices. Unlike flow meters, smart water control systems can recycle the same seal flush water multiple times, replacing it with fresh cold seal water when necessary. In systems with high temperatures, these smart water control systems offer reduced water savings as they are frequently topping off with cold water.

When selecting a water control system, end users should look for devices that operate automatically, do not require power, easily integrate with existing equipment and have minimal maintenance requirements. Other desirable features include high-quality filters to remove impurities from the seal water and backup safety valves to drain seal water in the event of operational issues. Installation can take as little as half an hour and does not necessitate specialized equipment.

Seal water pots

Closed-loop seal water systems, commonly used in pulp and paper plants, are another alternative for seal water conservation. These systems employ a pressurized seal water pot that holds several gallons of water and connects to the seal via hoses. The system continually circulates the same water between the seal and the tank, reducing seal water use and eliminating wastewater discharge. However, these systems can be expensive to install and require regular maintenance to refill with fresh water and remain operational. If process fluids mix with seal water due to seal damage or wear, cleaning the seal pots can be challenging.

Water filtration

Filtration is essential to ensure efficient water use in a system. Impurities in water can build up over time, clogging pumps, increasing wear on seals and other system components and ultimately leading to increased seal water consumption as users attempt to prevent clogging in their system-regulating valves. End users should ensure their seal water adheres to their industry specific standards for optimal performance, including limits on impurity size, silicate content, organic impurities, iron content and water hardness.

Depending on the flush water system requirements, end users can choose from various filtration options, such as inline filters for individual applications or multilayer filters for plantwide systems.

Benefits of Water Conservation

Reducing seal water consumption reduces water and wastewater treatment costs, while also enhancing system reliability and reducing maintenance expenses. Seal water-related issues are responsible for 59% of seal failures, with most failures stemming from impurities accumulating in the system and leading to blockages. System wear can also cause seal water to infiltrate process fluids, compromising the quality of end user products. In systems without seal water controls, seals typically have a life span of six to 18 months. With appropriate seal water flush control technology, end users can extend their seal life span by several years, achieving improved equipment uptime, enhanced system performance and lower maintenance costs.

Minimizing seal water consumption can help end users meet environmental standards, as many government bodies are tightening regulations on water pollution and excessive water usage. This puts pressure on plants to reduce wastewater production and overall water consumption to comply with these regulations.

Efficient seal water usage is achievable with the aid of current water conservation technology. By investing in system controls and adhering to best practices, end users can realize significant financial, operational and environmental benefits.

We invite your suggestions for article topics as well as questions on sealing issues so we can better respond to the needs of the industry. Please direct your suggestions and questions to sealingsensequestions@fluidsealing.com.