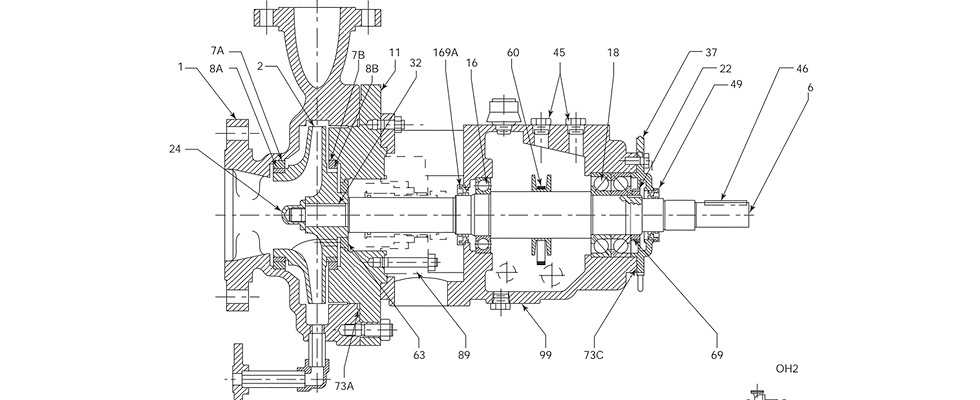

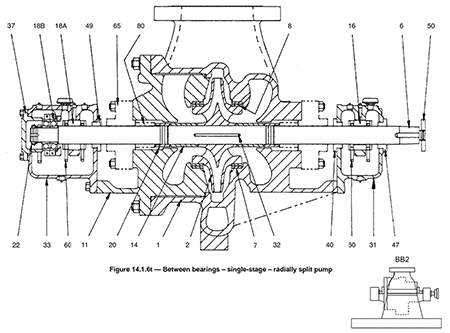

Pumps used in refinery service are typically manufactured to American Petroleum Institute (API) standards. API 610 covers centrifugal pumps, API 674 covers reciprocating pumps, API 676 covers rotary pumps, API 685 covers centrifugal sealless pumps and API 682 covers shaft sealing systems for centrifugal and rotary pumps. Generally, pumps covered by these standards include design requirements to accommodate refinery challenges, such as high temperature and pressure and the desire to maximize reliability and safety. This results in pumps designed per these standards being higher cost than a general industry pump. For example, single stage centrifugal pumps will often be of the OH2 (Image 1) and BB2 (Image 2) configurations, which have radially split casings for sealing high pressure and centerline mounted casings for even thermal expansion at high temperatures.

For more information, refer to Hydraulic Institute (HI) Standard, Rotodynamic Pumps for Nomenclature and Definitions (American National Standards Institute [ANSI]/HI 14.1-14.2) at pumps.org. To learn more about pumps used in refinery services, refer to api.org.