Each week, there seems to be another news story about record-breaking storms ravaging cities and their surrounding infrastructure. Atmospheric rivers, floods, hurricanes and other severe weather events are likely to increase over the next few decades in frequency or in severity. Regardless of cause, these more intense weather events can overwhelm the existing, often outdated, stormwater infrastructure designed for a lower average rainfall.

This growing concern begs the question: What opportunities are there to reevaluate existing stormwater infrastructure to handle this new normal? This article will explore the value of software modeling to identify existing flaws, present new opportunities and ensure updated designs are adequate for the growing demands on stormwater systems.

This will follow a case study evaluating a failing industrial stormwater system to demonstrate a typical approach to software modeling and the benefits this process has to offer.

.png)

Constant Flooding in Gulf Coast Refinery

The Gulf of Mexico coast averages some of the highest rainfall in the United States. As a result, cities like Houston and the surrounding industrial complexes require ample infrastructure to avoid stormwater flooding. Without this infrastructure, frequently flooded process areas can create a hazard for operators and operations alike.

An engineering firm was tasked with evaluating a failing stormwater system for a Gulf Coast refinery. There was a general awareness among plant personnel that the existing system could not keep up with stormwater demands during significant rain events, evident by extensive flooding of process areas.

Many operations to prepare the system during a storm event were manual, often delayed until rain intensity began to lessen. Undersized or degraded infrastructure further exacerbated the inadequate response by the existing system. Of the system’s eight lift stations (where stormwater is pumped from gravity drain collection sites through headers to dedicated storage tanks), only three stations had capacity for a five-year storm event as found in Image 1.

Stormwater systems are typically designed for a single, instantaneous peak flow rate derived from a chosen rain event to eliminate flooding. Due to the limited capacity of existing infrastructure, dramatic upgrades and additions would be required to achieve a no-flooding condition.

As an industrial site, the team pivoted to instead design for total rain volume from a 25-year storm event, setting tolerable inundation depths and maximum pump out times as criteria for the proposed solutions.

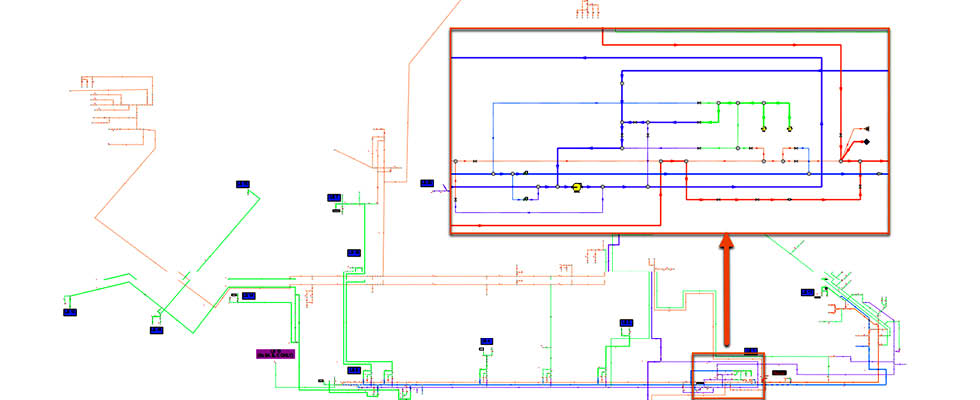

Building a Representative Model

The engineering firm’s team began their analysis by constructing a software model of the existing piping infrastructure from drawings, design data, field observations and other available information sources such as component data sheets for pump curves and valve losses. The finalized model can be found in Image 2, color coded and labeled for ease of use by the team.

This initial model draft was then calibrated using the more than 160,000 data points the team collected at critical points in the system. This calibration step ensures that any modeled modifications to the system will be representative of the final physical system.

Calibration included degrading pipes and pumps, adjusting valve position and capturing unique losses through flow elements like strainers, filters, mixers, etc. The team was able to calibrate the 505-pipe model to within 3% accuracy of measured field data. Much of this calibration was automated using built-in software tools to iterate variables like pipe roughness or pump speed to achieve the measured values.

Evaluating Design Alternatives

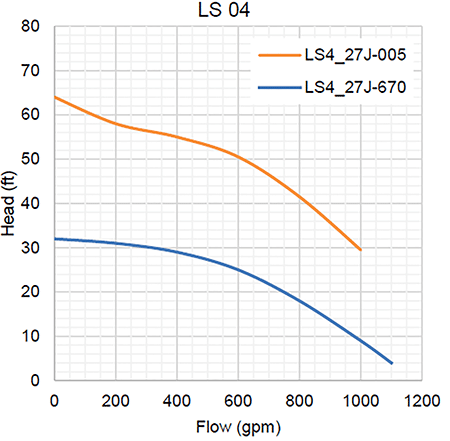

With a calibrated model in hand, the engineering firm could evaluate the existing system to identify shortcomings and improvement opportunities. One flaw was the mismatching of parallel pump curves in four of the eight lift stations. Parallel pumps are typically identical to ensure the workload is shared equally between each pump.

For mismatched pumps, one pump may operate at its deadhead condition while the other pump carries the entire workload. An example of this mismatch is found in Image 3, in which operating at a head requirement above 32 feet effectively deadheads the smaller pump.

The comprehensive model allowed the engineers to experiment with design solutions at various cost levels, with each variation managed in a single model file. No-cost designs which only changed to valve operation increased capacity by 11%. Low-cost designs to upgrade the lowest performance lift stations and repurpose an existing line as a parallel fill line could increase capacity by 33%. While capacity was improved dramatically in both no- and low-cost cases, capital cost was required to meet the desired inundation levels and pump out time targets.

The team proposed three capital cost options to meet these requirements, including upsizing piping, adding an additional lift station, installing a new header and stormwater tank and upsizing or replacing pumps. The combination of these suggestions increased stormwater capacity by 151% to meet the design requirements.

While addressing the flooding concerns was the primary purpose of the study, the engineering firm’s analysis was also serving as a second opinion on $70 million recommendations from a larger, incumbent firm. Even at the highest expenditure level, the firm’s approach to build, calibrate and design in software revealed a solution at 65% of the other firm’s cost, while also providing lower-cost options if the client’s requirements shifted.

Software for Stormwater Design

The evaluation of the stormwater system distills the essence of software-based engineering design. It demonstrates the process to build a model from drawings, calibrate to be representative of the final physical system, then experiment and iterate to meet the new design requirements.

As stormwater demands continue to shift, it is essential that the infrastructure designed to handle these demands shifts with it. While this study focused on industrial applications, it is even more important to consider the effects on life and property even one extreme storm event can cause.