Will a system curve look the same for pulp or viscous applications as it does for water?

Pumps

Cody Bann of WIN-911 shares steps to improve cybersecurity at a wastewater plant.

The system should be in compliance and integrated into an existing SCADA environment.

Benefits include solvent recovery, construction flexibility and cost savings.

Most of the infrastructure supplying 5 major petroleum companies needed rehabilitation or replacement.

How design differences affect system dynamics and how to account for these effects.

Pumps for fracking must deal with high pressure extremes.

Some key inputs used in manufacturing semiconductors come out of Russia and Ukraine.

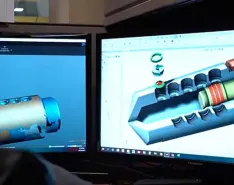

Why twin-screw pumps handle different viscosities and other liquid characteristics well.

The list of recommended spare parts will depend on the pumping design and other factors.

Repairing a pump using coatings can cut down on cost and energy use.

Understand how hydrogen and CCUS can help industry and country meet their ambitions.

The ins-and-outs, basics and risks of RE and how it can help your plant.

Wastewater plant’s performance was impacted by large debris.

Listen to hear about what's in the March issue and why upgrade cores are important.

Economic growth was robust throughout 2021 as vaccinations increased and stay-in-place behaviors began to abate.

Learn why groundwater management is more controlled and stormwater management is more challenging.

Who will win the IIoT arms race? Hydro's Ares Panagoulias discusses that and more.

There are no fixed rules for selecting the pump type for a specific boiler feed application.

Columnist Lev Nelik discusses pump selection in part two of this two-part column.

Hybrid work environment a positive change coming from pandemic, Loudin says.