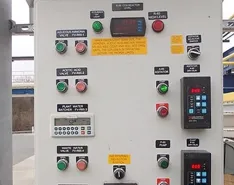

Power sensors can positively affect efficiency and contribute to energy savings.

Motors

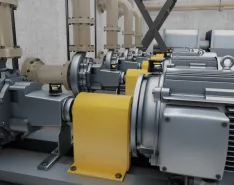

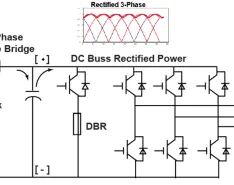

Motors are the most common source of power used by pumping systems. This technology is heavily regulated. Pumps by themselves are not variable speed, an option that many systems need to operate with peaks and ebbs during the run cycle, such as power generation. The addition of a variable frequency drive (VFD) gives it that capability.

Actionable steps you can take to raise your pumping standards while lowering costs.

Review a comparison of submersible and immersible motor types.

Consider several factors when choosing and implementing sensors for your monitoring program.

Operators can improve accuracy and minimize costs.

Consider cabling, size and windings in order to make the right choice.

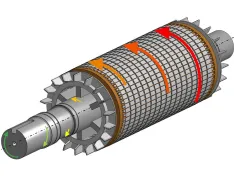

In some instances, operating a motor beyond the base pole speed is possible and offers system benefits if the design is carefully examined

Although many could still not get away from small businesses to attend, international attendees helped bring attendance to prior numbers.

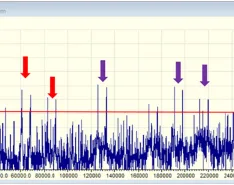

This test can find cases of weak insulation before the motor progresses to complete failure.

Understand three considerations for evaluating your next efficient motor.

Users have several needs and goals in order to upgrade the pump system.

What to know about these motors in pumping applications.

Failing grids can result in interruptions across many platforms.

Although still in its infancy, electrical signature analysis can offer long-term benefits to users.

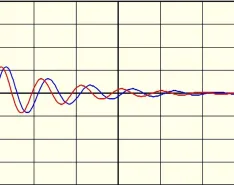

Understand how resonance and drivetrain design issues might be behind vibration problems.

Podcast also hits on the June 2022 issue of Pumps & Systems.

VFDs are used to control the speed of both induction and synchronous motors.

Learn how to protect your pump motors from damage.

Follow these simple steps for preseason preparation.

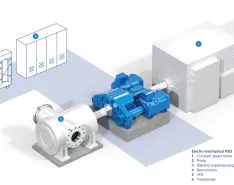

Electromechanical VSDs can provide high efficiency for high-power, high-speed pumps.

The complexity of pairing a motor with a VFD is a key point to consider, along with torque.